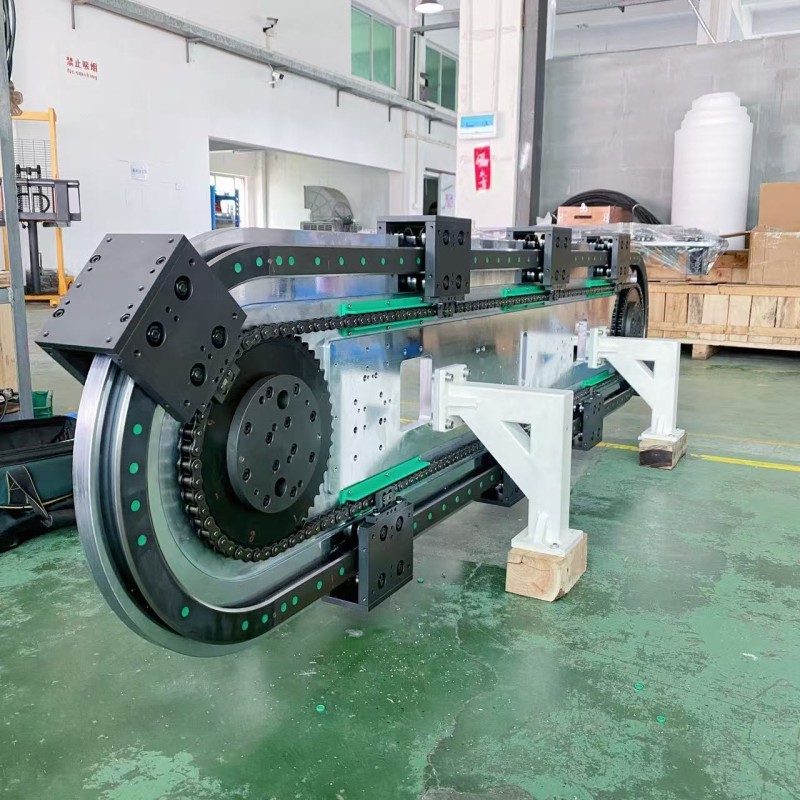

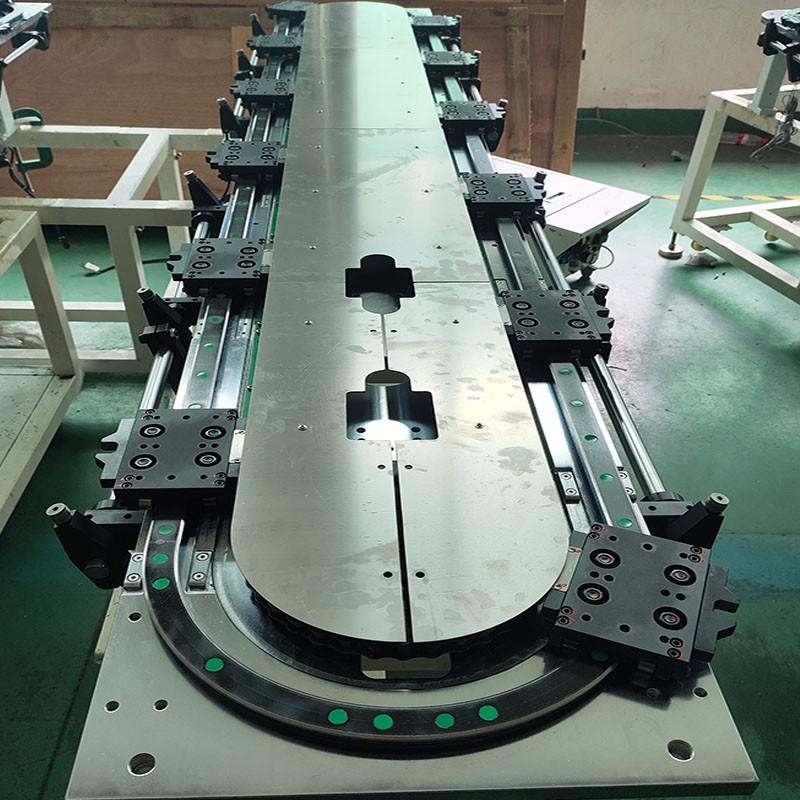

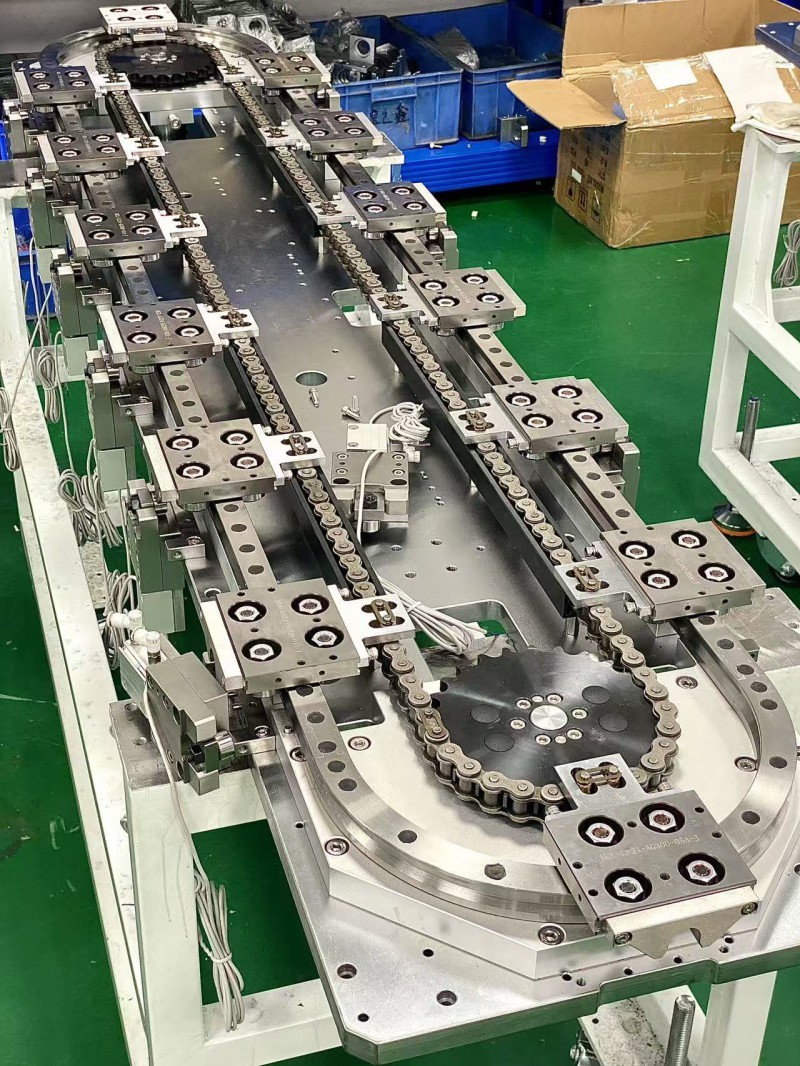

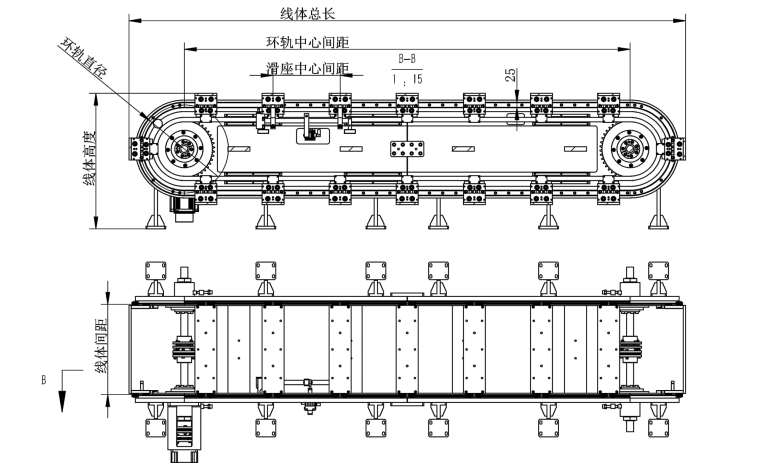

Vertical floor double track precision arc guide rail

Email:

tanhaofeng09@gmail.com

Still deciding? Get samples first, Contact US !

View similar products

Vertical ring guide rails

Tag list

Description

Installation method: vertical

Transmission method: chain

Single track conveyor

Positioning accuracy: ±0.05mm

Structural properties

Vertical architecture: The innovative vertical design makes full use of vertical space and greatly reduces the occupation of valuable floor area. This layout is particularly suitable for factory environments where production space is limited but efficient material flow is required.

Dual-track system: equipped with two parallel and independent tracks, which significantly enhances the overall stability and load-bearing capacity of the conveyor line. The two tracks work together to evenly distribute the weight of the material, effectively avoiding shaking or deformation caused by excessive force on one side.

Double bottom plate design: The double bottom plate not only increases the area of contact with materials and improves the stability of material placement, but also allows different tooling fixtures or conveying processes to be set up on the upper and lower bottom plates according to different production needs to realize the processing of a variety of materials. Or the synchronous processing of different processes of the same material greatly improves production efficiency and flexibility.

Application scenarios:

1. Automobile manufacturing industry

Application process:

a: Automobile parts assembly, such as automobile battery assembly

b: Automobile parts manufacturing, such as automobile brake disc processing

c: Automobile lamp detection, such as automobile headlight detection

2. Injection molding industry transportation

Application process:

a: Injection molding parts transportation, such as surprise egg packaging

b: Injection molding toy manufacturing, such as automobile model conveying processing

c: Injection molding toy detection, such as building block matching detection

Vertical floor double track precision arc guide rail

Still deciding? Get samples first, Contact US !

Products Category

Vertical ring guide rails

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!