Precision Curved Guides Factory

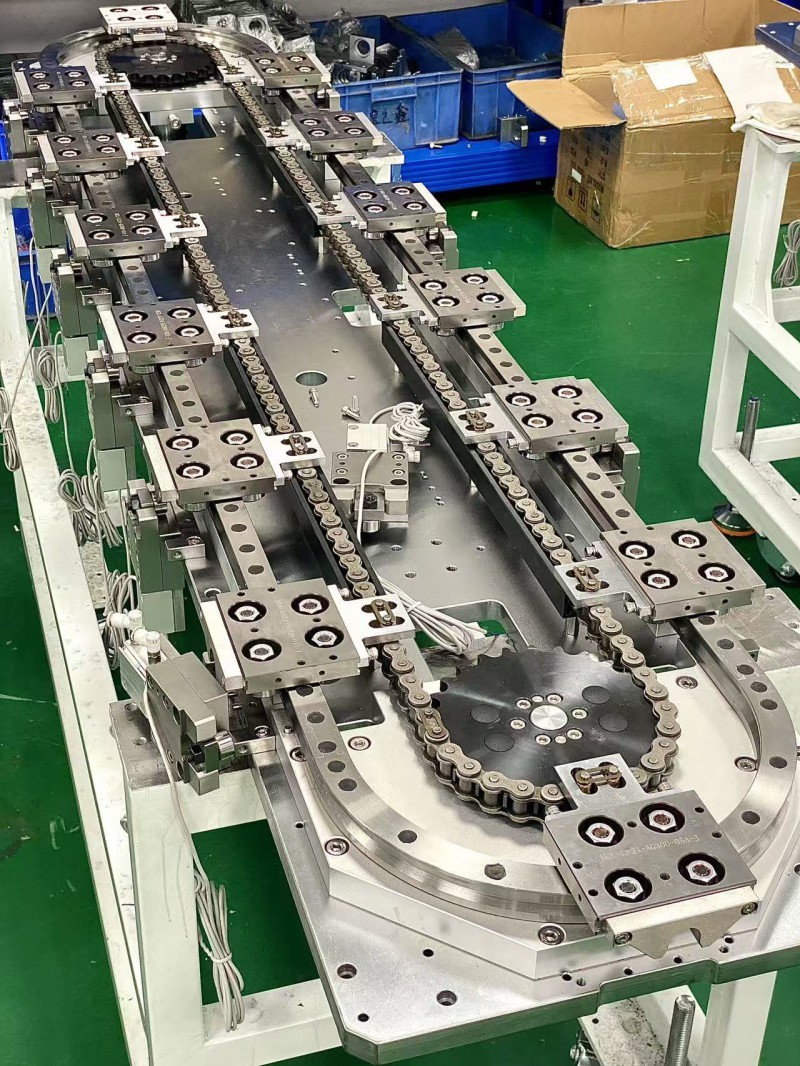

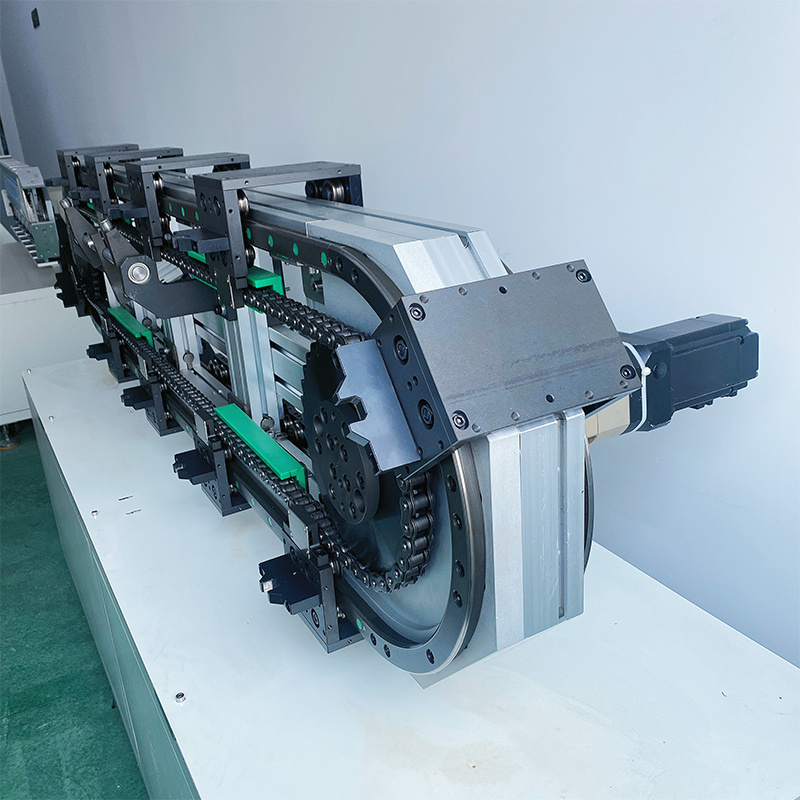

Driven Track Systems Manufacturer

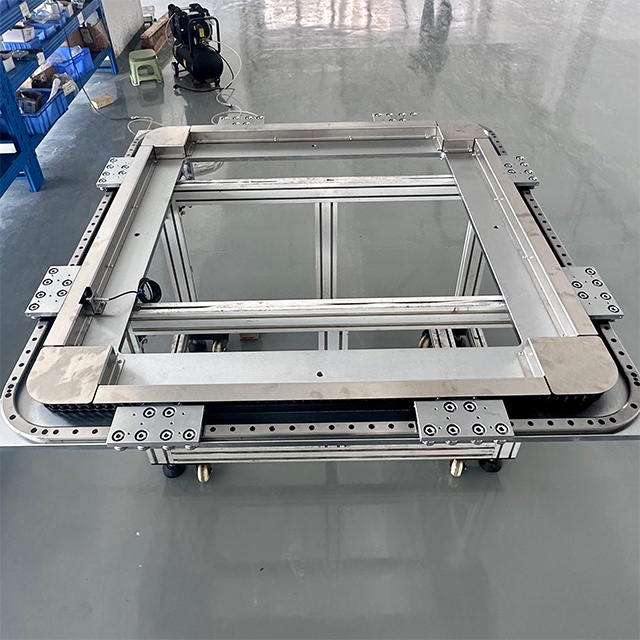

vertical conveyor with two parallel curved rail

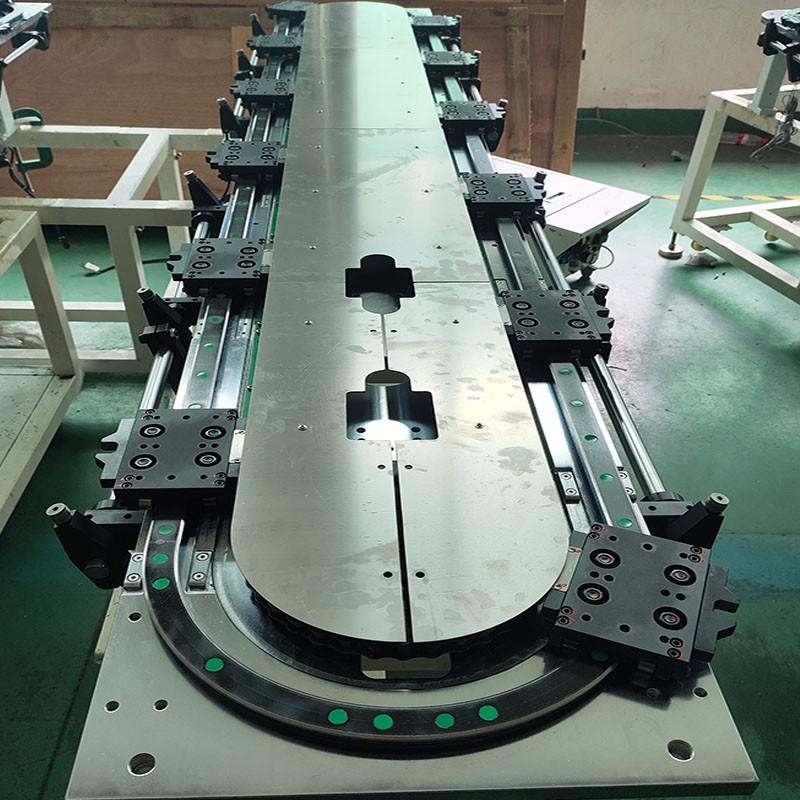

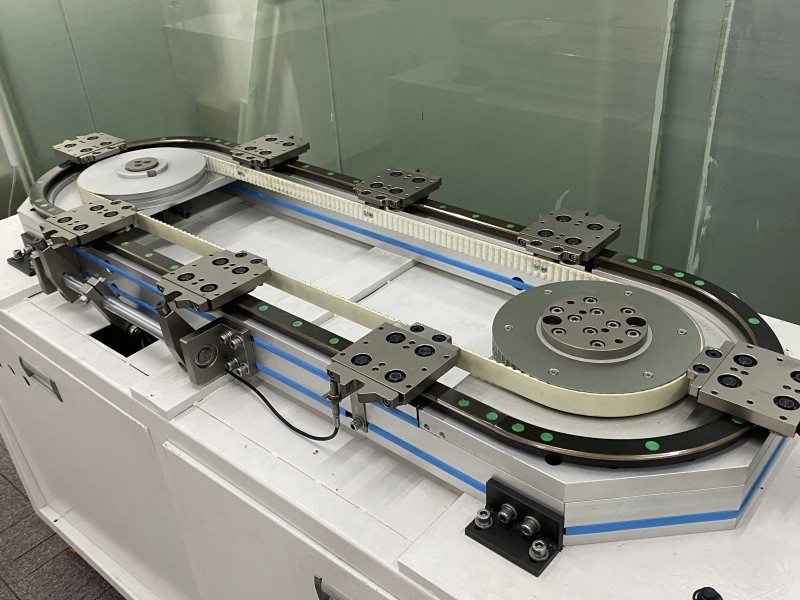

rectangle circular conveyor Application in rotating display stand

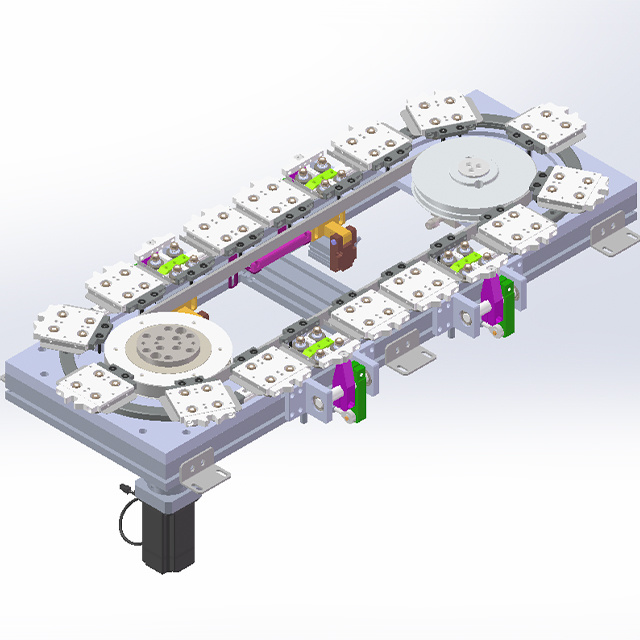

Precision Circular Conveyor System High-Performance Industrial Automation Solution

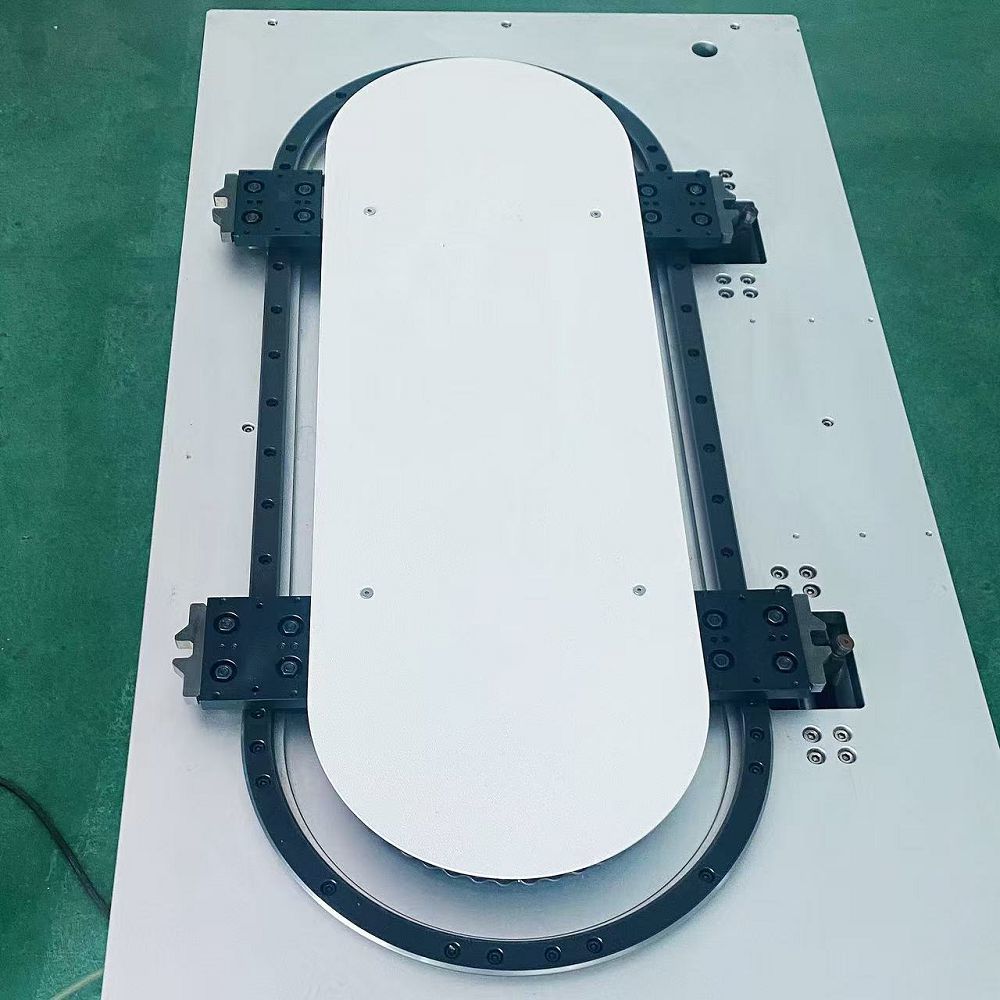

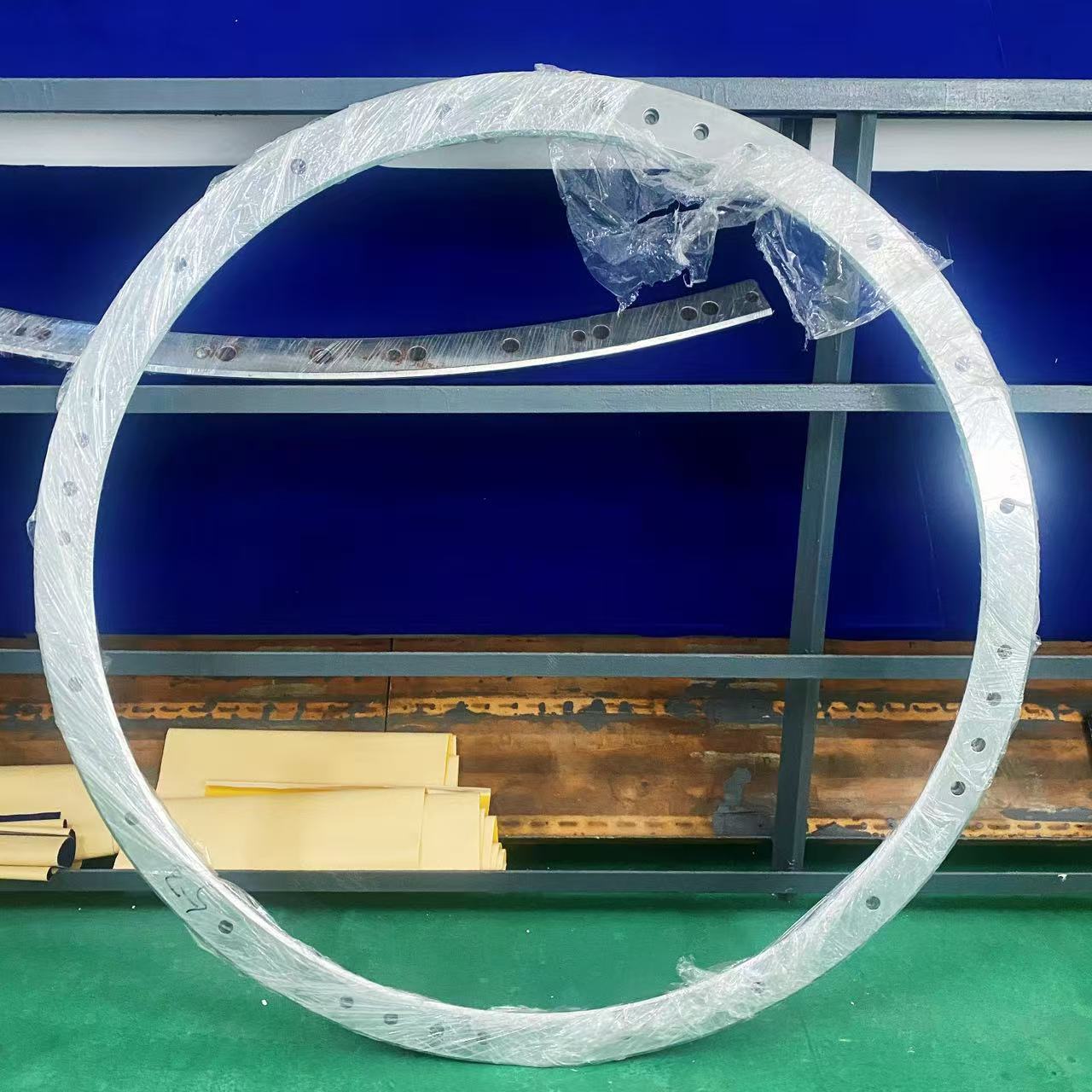

Ring Rail System High-Precision Circular Guide Rails for Industrial Automation

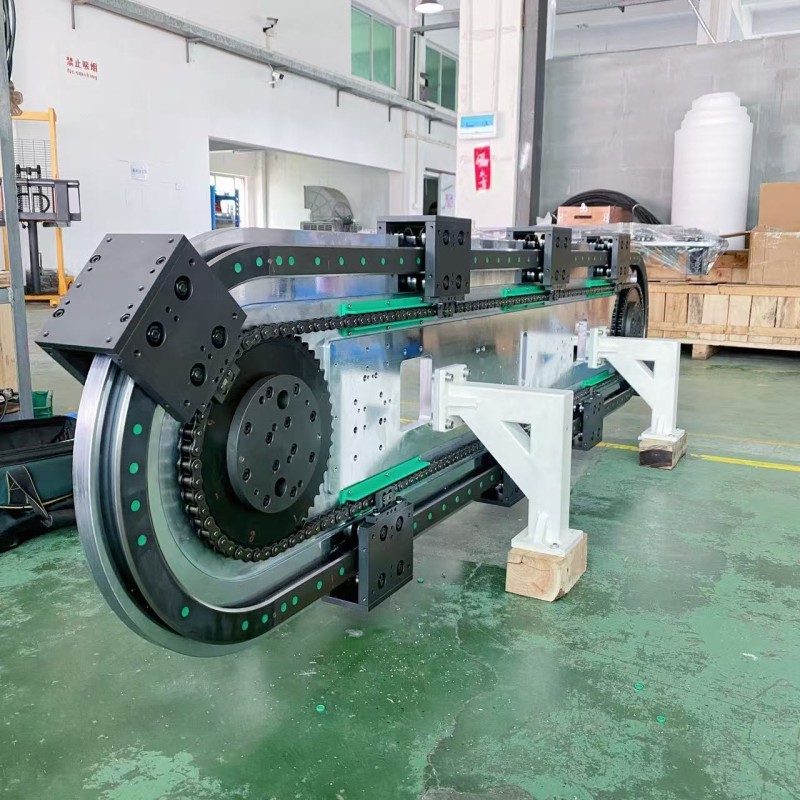

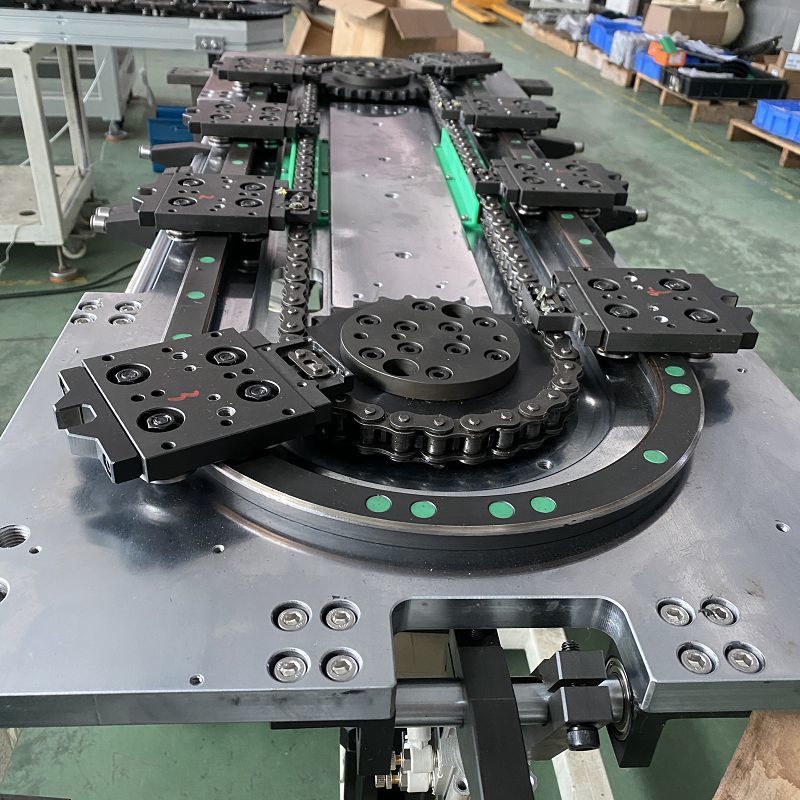

HD–RT Heavy Duty Ring Guides and Track Systems

LOP – Guidance System for Linear Guide System

PR-T2 Precision Curved Guides, Rings and Segments

DT-S2 High Speed Driven Track System