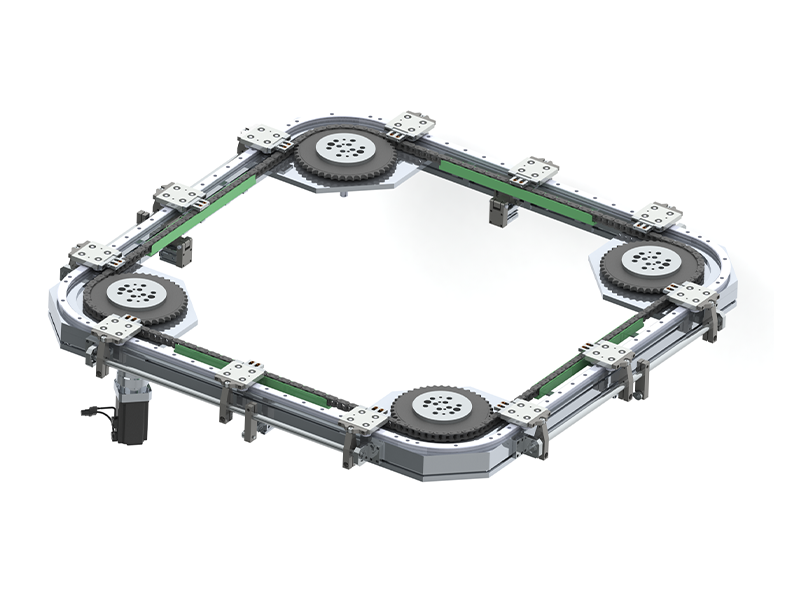

Chain ring guide conveyor line

The rectangular chain ring guide is a high-precision, highly flexible automated circulating linear track, which is used in various precision machining automation equipment.

Application areas

V-type guideway Belt Curved Rails

By rationally selecting the specifications and tooth profile parameters of the synchronous belt, the transmission ratio and conveying speed can be flexibly adjusted according to different production requirements to meet the conveying tasks under various working conditions.

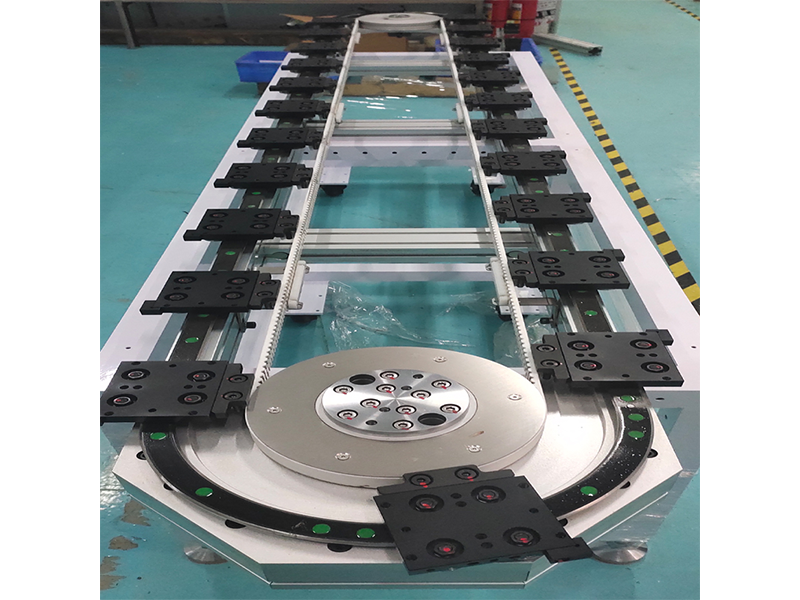

The use of synchronous belt as a power transmission component is an important feature of this conveyor line. The synchronous belt has a precise tooth structure, which is tightly meshed with the synchronous pulley to ensure the accuracy and stability of power transmission.

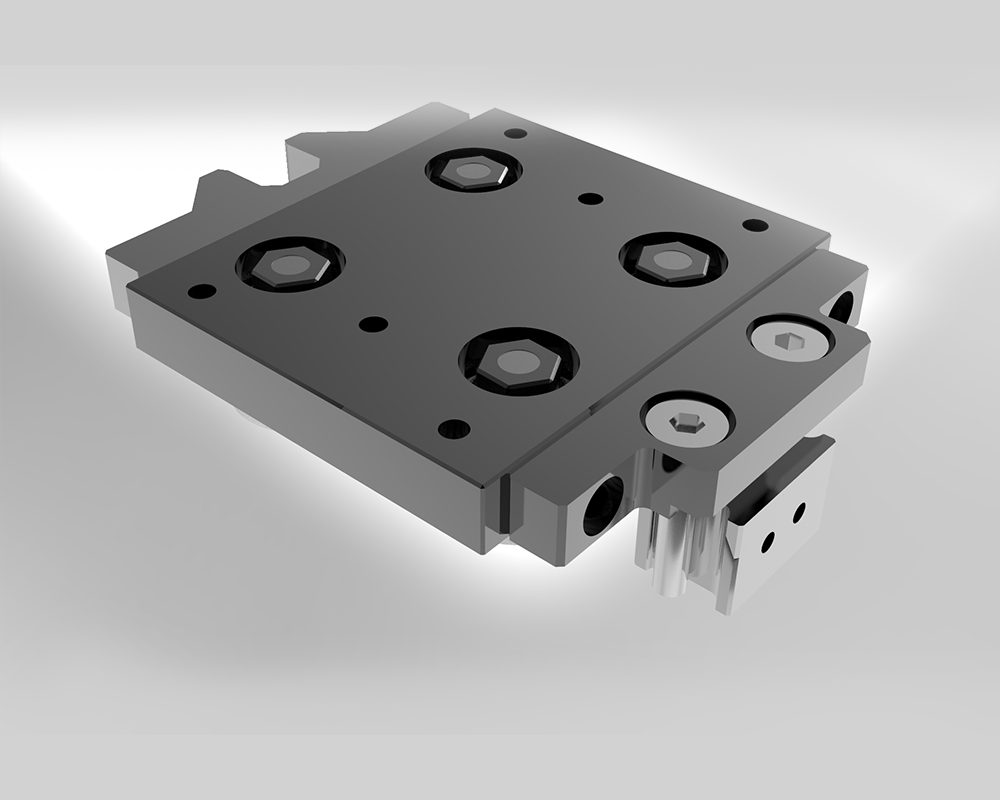

As a key component for carrying materials, the slide is installed on the synchronous belt and slides on the elliptical ring guide. The slide and the synchronous belt are connected by a reliable connection device to ensure that the slide can move stably with the synchronous belt.

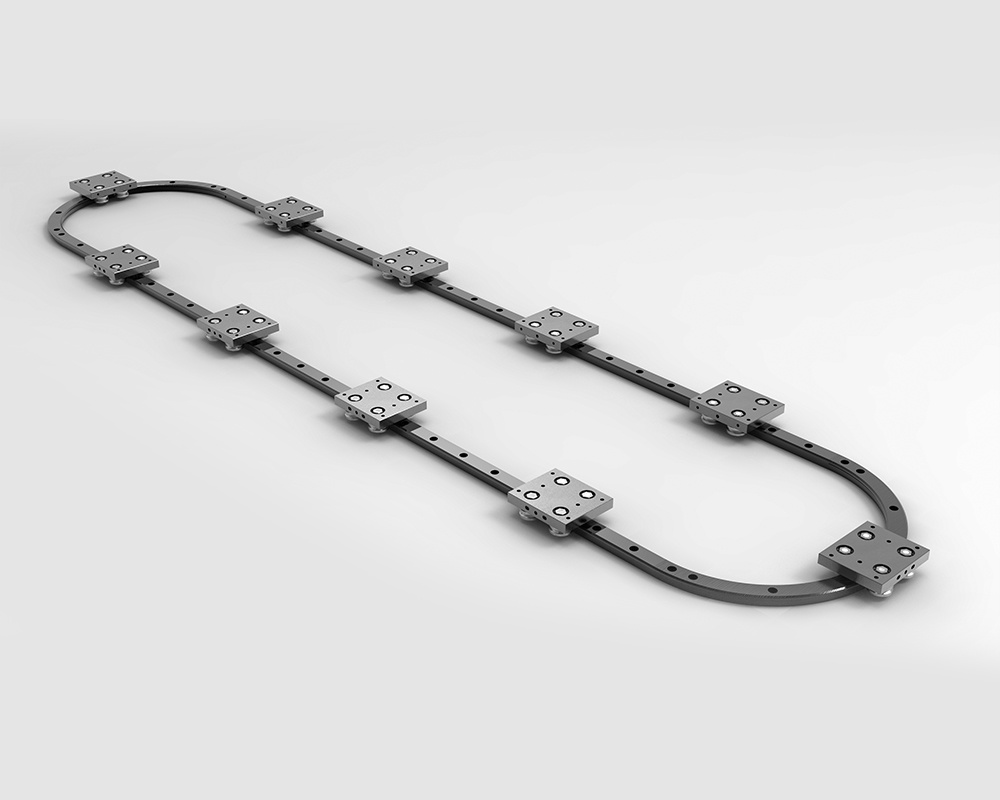

The shape of the special-shaped circular guide rail can be customized according to specific application requirements. Common shapes include ellipse, polygon, irregular curve, etc. This unique shape design enables the guide rail to adapt to different working environments and space constraints, providing a more flexible motion solution.

The shape of the special-shaped circular guide rail can be customized according to specific application requirements. Common shapes include ellipse, polygon, irregular curve, etc. This unique shape design enables the guide rail to adapt to different working environments and space constraints, providing a more flexible motion solution.

V-type guide rail + work station

The guide rail is V-shaped and is usually made of high-quality steel or aluminum alloy. The V-shaped guide rail design can provide better guidance and stability, ensuring that the slide maintains a straight line during movement.

The slide is a component used with the V-type linear guide, usually made of high-strength plastic or metal. Rolling elements such as rollers or balls are installed on the slide, allowing the slide to slide smoothly on the guide rail.

Rectangular belt circular guide conveyor line

The rectangular synchronous belt circular guide rail is used in the automation production and manufacturing of light loads, high speeds, and high precision, requiring high spatial flexibility

Elliptical belt circular guide conveyor line

The synchronous belt driven elliptical profile circular guide conveyor system is commonly used in narrow production lines, such as the manufacturing process of various manual processes, especially in applications with low load-bearing requirements, high speed and high precision.

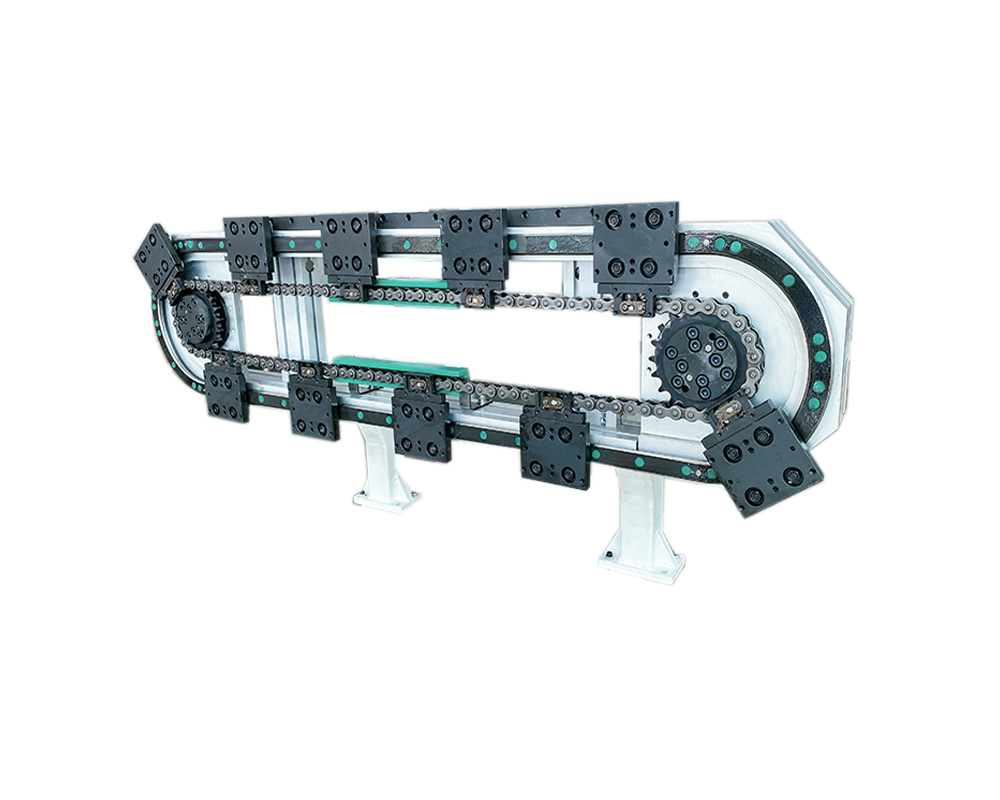

Rectangular chain circular guide conveyor line

Rectangular chain circular guide rail is an advanced mechanical transmission system with advantages such as high precision, high rigidity, low friction, and easy maintenance.

Elliptical chain circular arc guide rail

The elliptical chain circular guide rail is a mechanical transmission system

Vertical single track circular guide rail

The working principle of the vertical single track circular guide rail is to achieve the transportation and positioning of objects through the cyclic motion of the slider on the guide rail.

The working principle of a rack and pinion guide is to convert rotational motion into linear motion through the meshing of gears and racks. When the gear rotates, the teeth on the gear interact with the teeth on the rack, pushing the rack to move in a straight line along the guide rail. The motion accuracy and speed of the rack and pinion guide depend on the accuracy and speed of the gears, as well as the quality and installation accuracy of the guide rail.