Used in conjunction with sliders or rollers, the sliders or rollers roll on the surface of the rolling vertical guide rail to achieve smooth and precise movement of moving parts in the vertical direction.

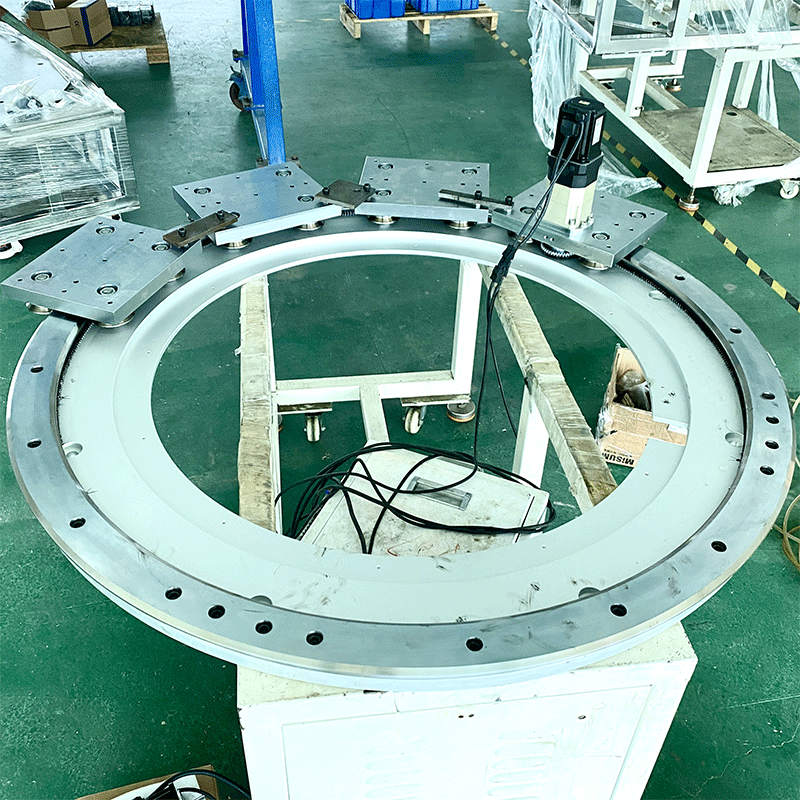

Circular Rails Heavy Duty Systems

Heavy duty circular guide rail system is an advanced mechanical equipment designed to carry heavy loads while achieving circular motion, widely used in multiple industrial fields.

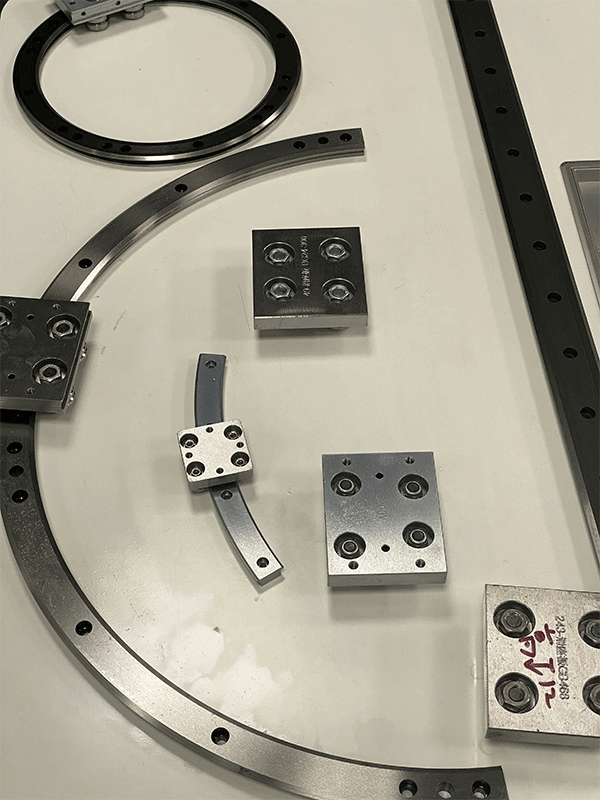

The slider is in direct contact with the guide rail, usually made of wear-resistant engineering plastics or metal composite materials. The surface of the guide rail is processed with high-precision grinding to ensure low friction coefficient and good sliding performance. Some sliding guides will have special coatings added to the surface to further reduce friction and wear.

Motion is achieved through relative sliding between the slider and the guide rail. During the movement, the slider slides along the surface of the guide rail, reducing frictional resistance through lubricants or special material properties to ensure smooth movement of the slider on the annular guide rail.

The working principle of a rack and pinion guide is to convert rotational motion into linear motion through the meshing of gears and racks. When the gear rotates, the teeth on the gear interact with the teeth on the rack, pushing the rack to move in a straight line along the guide rail. The motion accuracy and speed of the rack and pinion guide depend on the accuracy and speed of the gears, as well as the quality and installation accuracy of the guide rail.

Pinion drive large diameter ring guides

The working principle of a rack and pinion guide is to convert rotational motion into linear motion through the meshing of gears and racks. When the gear rotates, the teeth on the gear interact with the teeth on the rack, pushing the rack to move in a straight line along the guide rail. The motion accuracy and speed of the rack and pinion guide depend on the accuracy and speed of the gears, as well as the quality and installation accuracy of the guide rail.

The curved motion of the V-shaped guide rail relies on the cooperation between the V-shaped guide rail and the V-shaped roller to achieve curved guidance. The V-shaped roller rolls on the curved surface of the V-shaped guide rail. The V-shaped shape allows the roller to accurately travel along the curved trajectory of the guide rail during the rolling process, limiting the displacement of the roller in the direction perpendicular to the motion, thereby ensuring the accuracy and stability of the motion.

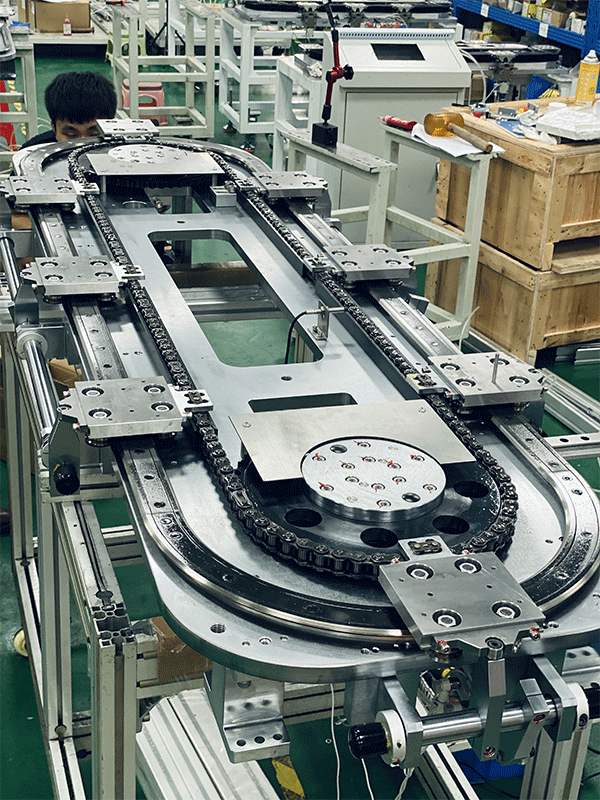

It is usually composed of a linear guide section, a circular arc guide section, and a slider. The linear guide section is used to achieve linear motion, the circular arc guide section is used to achieve circular arc motion, and the slider moves on the guide rail

After the driving device (such as servo motor) is started, it drives the active pulley to rotate. The active pulley drives the circular synchronous belt to move through friction, and multiple sliding seats are connected to the synchronous belt. The sliding seats move cyclically on the circular guide rail with the movement of the belt. The fixture is installed on the slide to achieve the transfer of workpieces between various workstations

It usually consists of a driving drum, a reversing drum, a tensioning device, a conveyor belt, and a supporting structure. The driving drum is driven by an electric motor through a reducer, and the conveyor belt is wrapped around the driving drum and the reversing drum. By relying on the frictional force between the driving drum and the conveyor belt, the conveyor belt circulates on the track, thereby achieving the transportation or movement of objects on the track

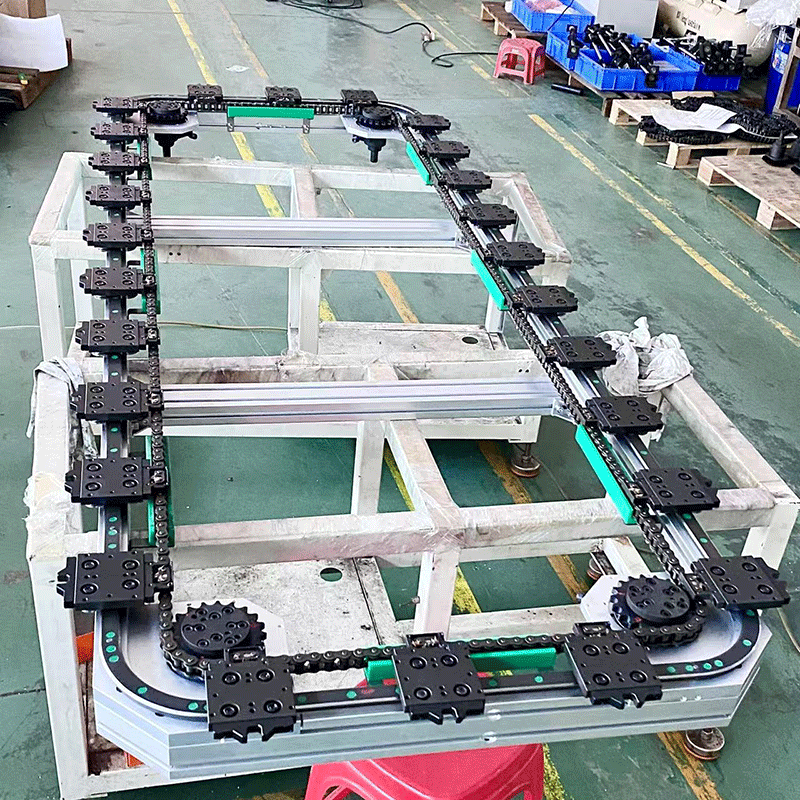

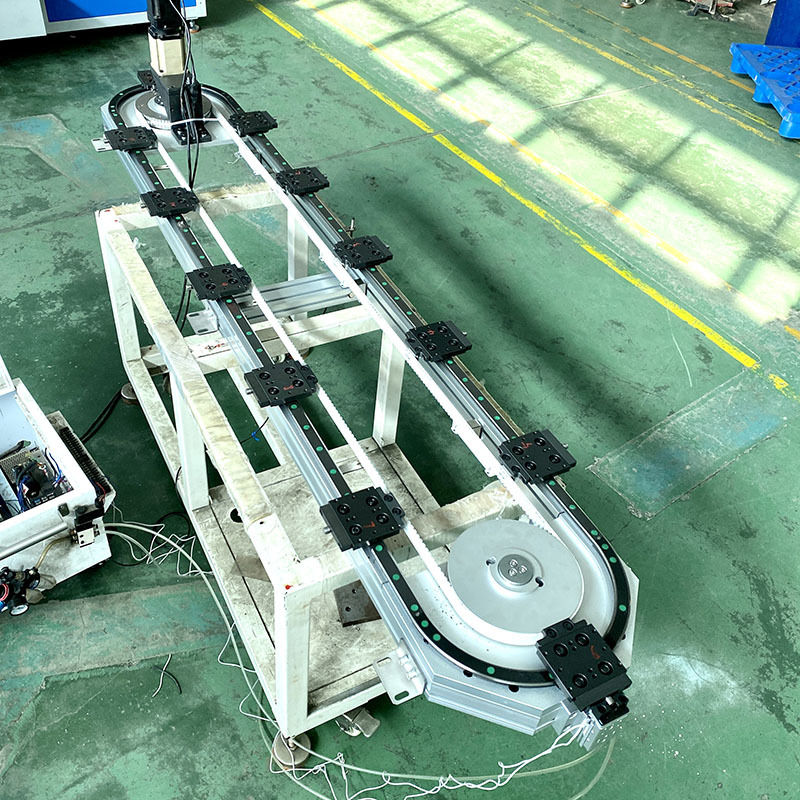

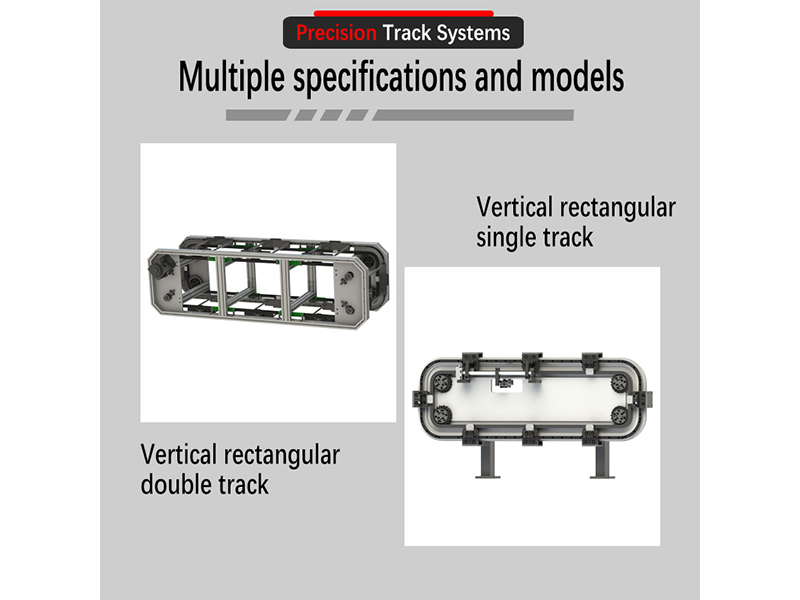

Vertical rectangular double track Circular guide rail circulation line

Different from the traditional horizontal conveyor line, the vertical double-track circular guide conveyor line adopts vertical installation, effectively utilizing the space height, and is suitable for use in production environments with limited space. The double-track structure increases the stability and carrying capacity of the conveyor line, and can accommodate multiple slides or fixtures at the same time, improving production efficiency.

Ring Guides Precision Track Systems

The elliptical ring guide provides precise guidance and support for the movement of the chain. The surface of the guide is finely processed to have a low friction coefficient, reducing the wear and energy loss of the chain during operation.