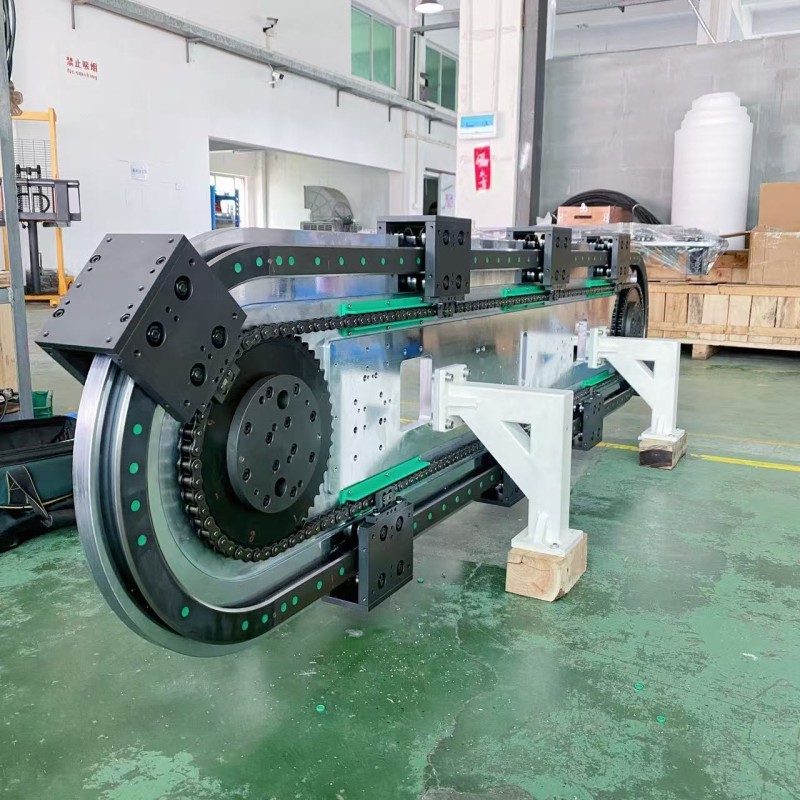

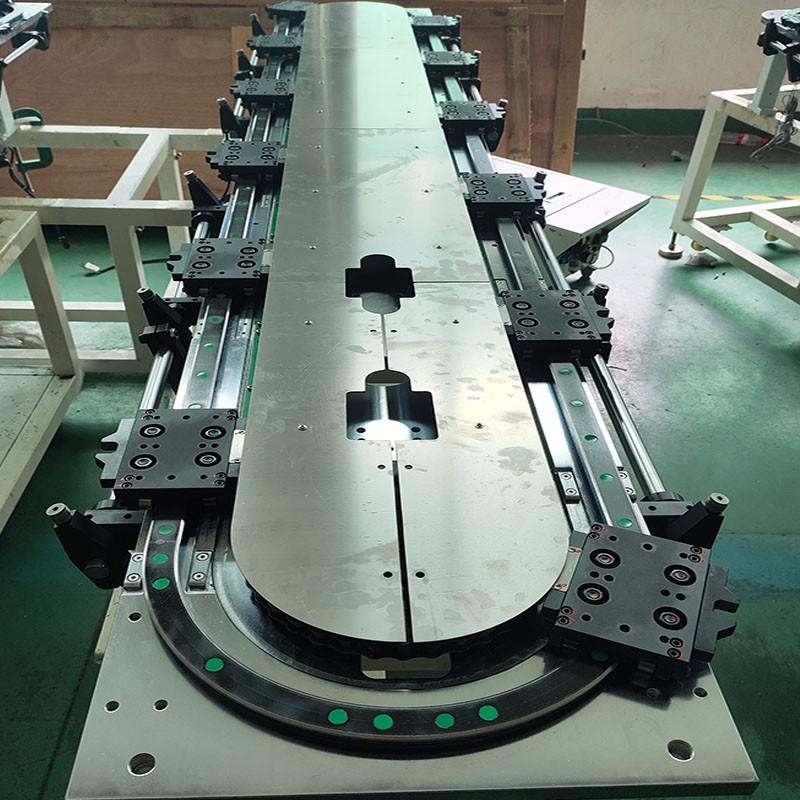

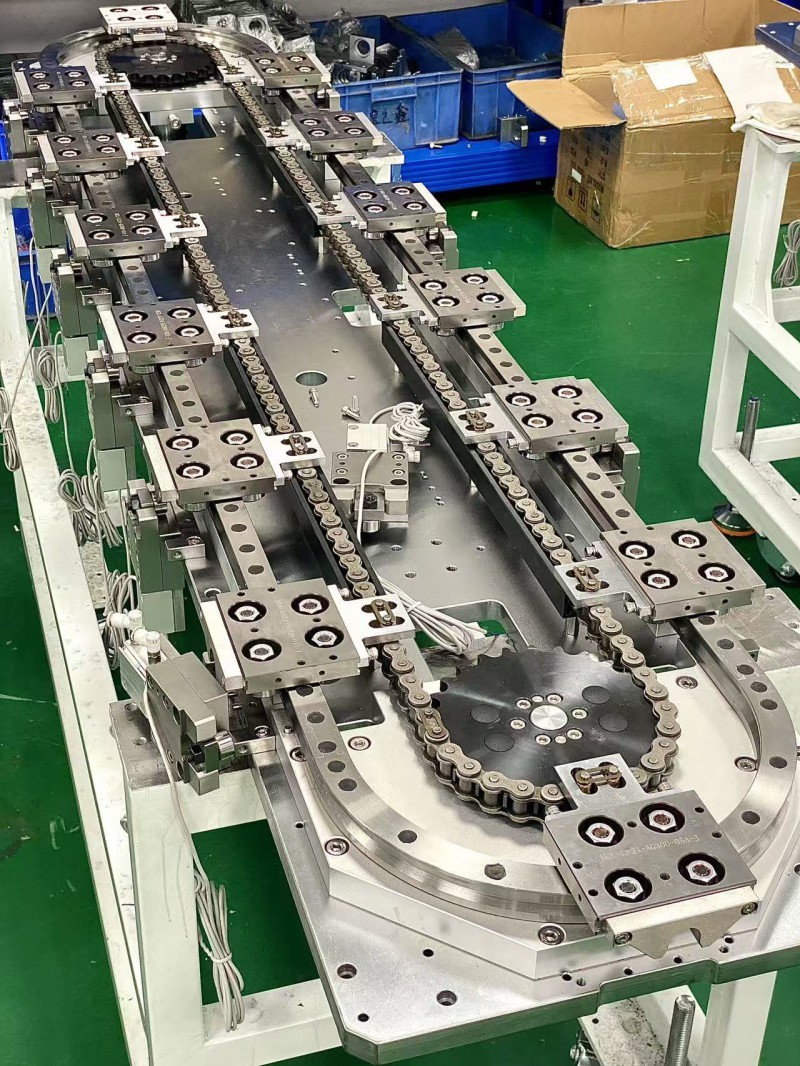

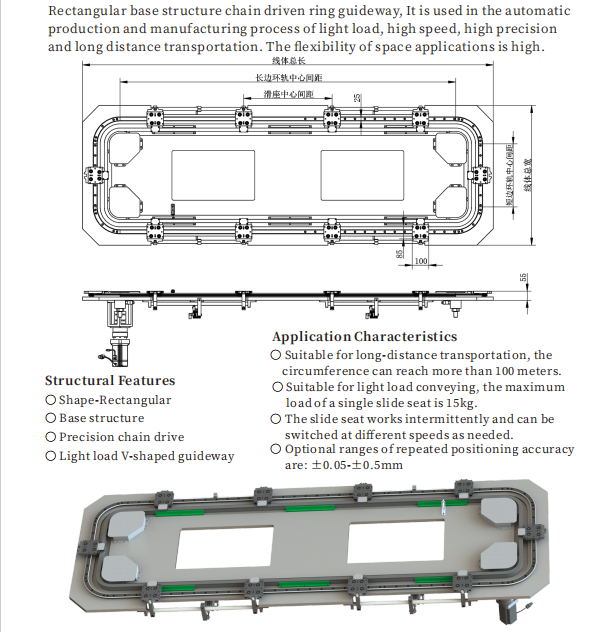

Rectangular double chain circular guide conveyor line

Email:

tanhaofeng09@gmail.com

Still deciding? Get samples first, Contact US !

View similar products

Chain ring guide rails

Tag list

Description

Load: High

Shape: Oval

Transmission method: chain

Positioning accuracy: ±0.05mm

Structural features

Rectangular layout combined with circular guide rails: The overall structure is a rectangular frame with circular guide rails installed inside. This unique combination not only takes advantage of the regularity and stability of the rectangular frame, but also makes the conveying path smoother and continuous, effectively avoiding the jamming and stagnation of materials during the conveying process.

Double chain transmission: equipped with two parallel chains as power transmission components. The double chain design greatly enhances the driving force and carrying capacity of the conveyor line, ensuring that the material is evenly stressed and runs smoothly during the conveying process, reducing the shaking or deviation caused by unilateral force, and improving the accuracy and reliability of the conveying.

Application fields

Automobile manufacturing: widely used in the production and assembly lines of automobile parts, such as the processing and assembly process of engines, transmissions, body frames and other parts. It can efficiently transport various parts between different stations to ensure the continuity and high quality of automobile production.

Mechanical processing industry: used for material transfer between the processing procedures of various mechanical parts, such as metal cutting, grinding, heat treatment and other processing links. It can achieve stable transportation of mechanical parts of different shapes, sizes and materials, and improve the overall efficiency and automation level of the mechanical processing production line.

Rectangular double chain circular guide conveyor line

Still deciding? Get samples first, Contact US !

Products Category

Chain ring guide rails

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!