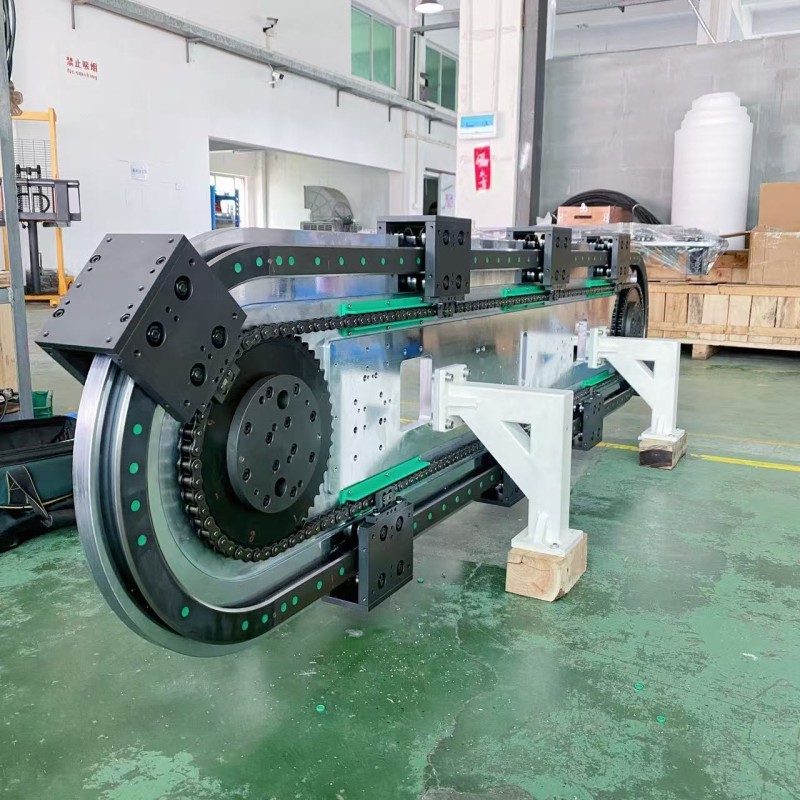

Driven track systems

Email:

tanhaofeng09@gmail.com

Still deciding? Get samples first, Contact US !

View similar products

Chain ring guide rails

Tag list

Description

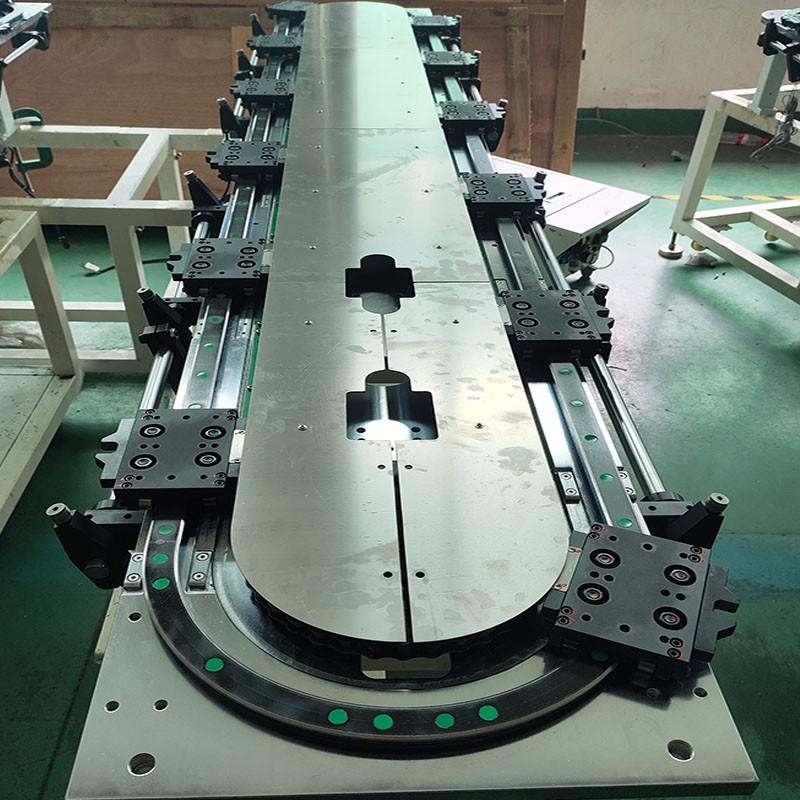

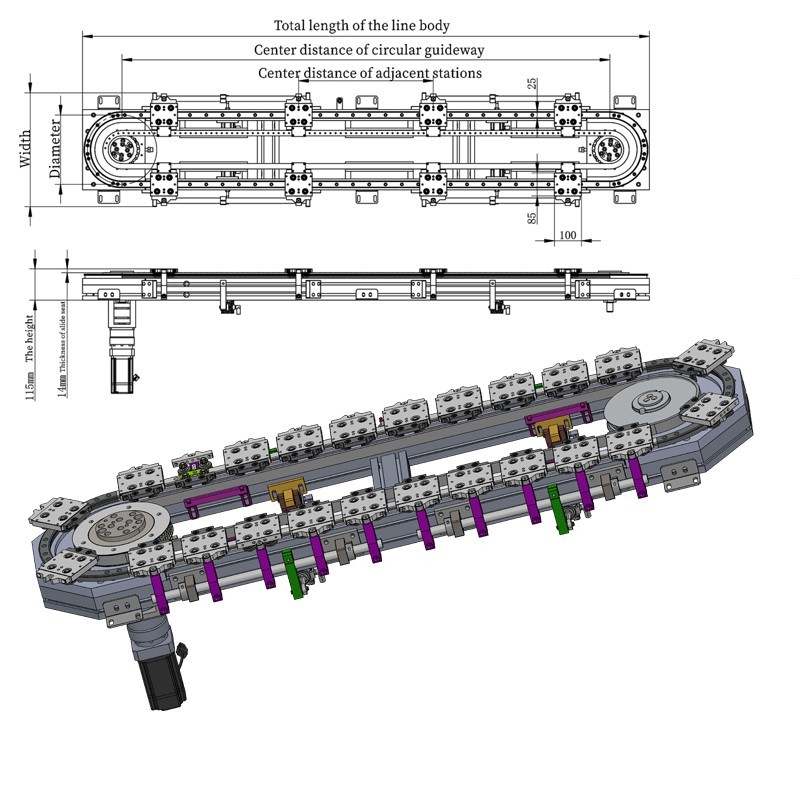

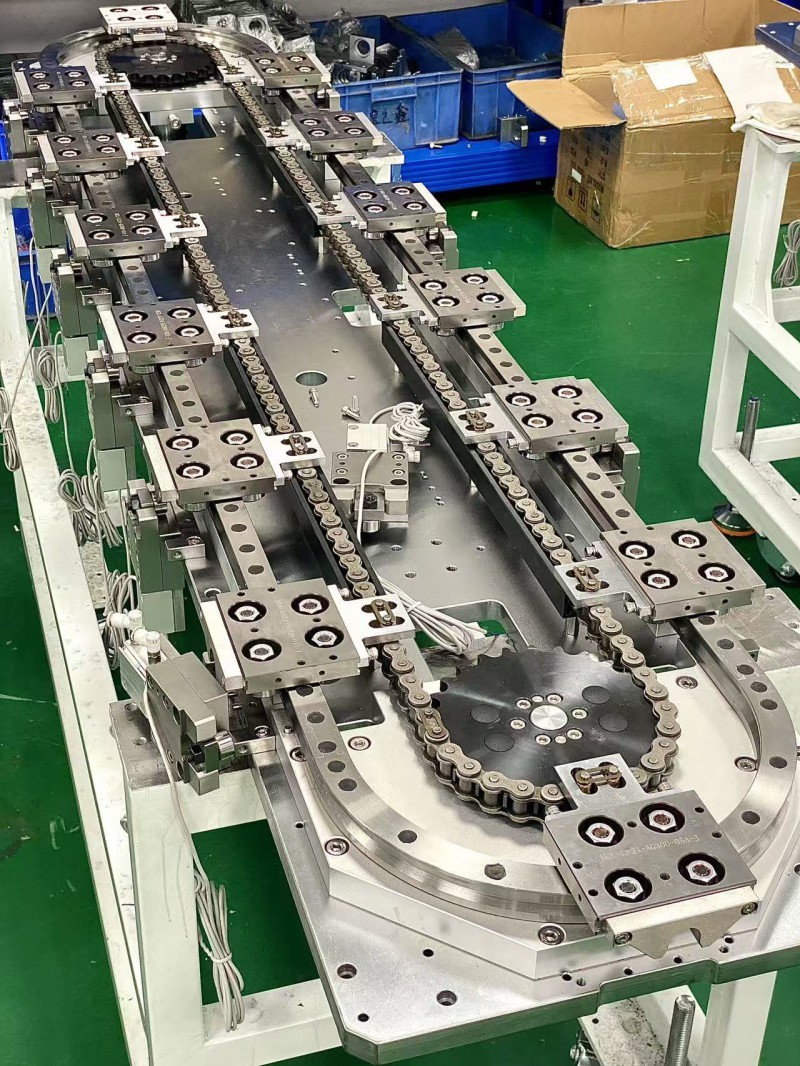

Our driven track systems are engineered for precision automation, these systems ensure low friction, high rigidity, and long service life, making them ideal for automated assembly, packaging, and material handling.

Key Features & Benefits

✔ Modular Design – Easy integration into existing production lines with customizable lengths and configurations.

✔ High Load Capacity – Supports heavy payloads with minimal deflection.

✔ Precision Bearings – Ensures smooth, low-noise operation with ±0.05mm repeatability.

✔ Corrosion-Resistant Coating – Special surface treatment for durability in harsh environments.

✔ Direct Drive or Belt-Driven Options – Compatible with servo motors for high-speed positioning

Applications in Key Industries

Automotive Manufacturing – Used in welding stations, robotic transfer systems, and engine assembly lines.

Electronics & Semiconductor – Ensures micron-level accuracy for PCB handling and component placement.

Medical Device Production – Hygienic, low-particulate design for cleanroom compatibility.

Packaging & Logistics – High-speed sorting and palletizing with minimal maintenance.

Why Choose Our Driven Track Systems?

Unlike standard linear guides, our systems feature preloaded bearings to eliminate backlash and hardened steel tracks for extended wear resistance. With IP65-rated sealing options, they perform reliably in dusty or wet conditions.

Request a Custom Quote Today! – Optimize your production line with our high-performance driven track systems.

Designed for high-performance automation, driven track systems deliver unmatched precision, reliability, and customization to streamline your production processes. Their modular design allows for easy customization in length and configuration, ensuring seamless integration into existing production lines. Whether supporting heavy loads or requiring micron-level accuracy, these systems excel with minimal deflection, thanks to their robust construction and high load capacity.

Precision is guaranteed with high-quality bearings, enabling smooth, low-noise operation and repeatability within ±0.05 mm—ideal for applications demanding extreme accuracy. A corrosion-resistant coating extends longevity, even in harsh environments, making these systems a durable investment. Choose between direct-drive or belt-driven options, both compatible with servo motors for high-speed positioning and superior motion control.

Driven track systems are widely used across industries. In automotive manufacturing, they optimize welding stations, robotic transfer systems, and engine assembly lines. The electronics and semiconductor sector relies on them for PCB handling and component placement with micron-level precision. Medical device production benefits from their hygienic, low-particulate design, which is suitable for cleanroom environments. For packaging and logistics, these systems enable high-speed sorting and palletizing with minimal maintenance.

Driven track systems enhance efficiency, reduce downtime, and achieve unparalleled precision, making them the ultimate solution for modern industrial automation.

Driven track systems

Still deciding? Get samples first, Contact US !

Products Category

Chain ring guide rails

Tag list

Previous Page:

Next:

Previous Page:

Driven Track Systems Manufacturer

Next Page:

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!