Exploring the Efficiency of Rectangle Circular Conveyors in Industrial Applications

May 05,2025

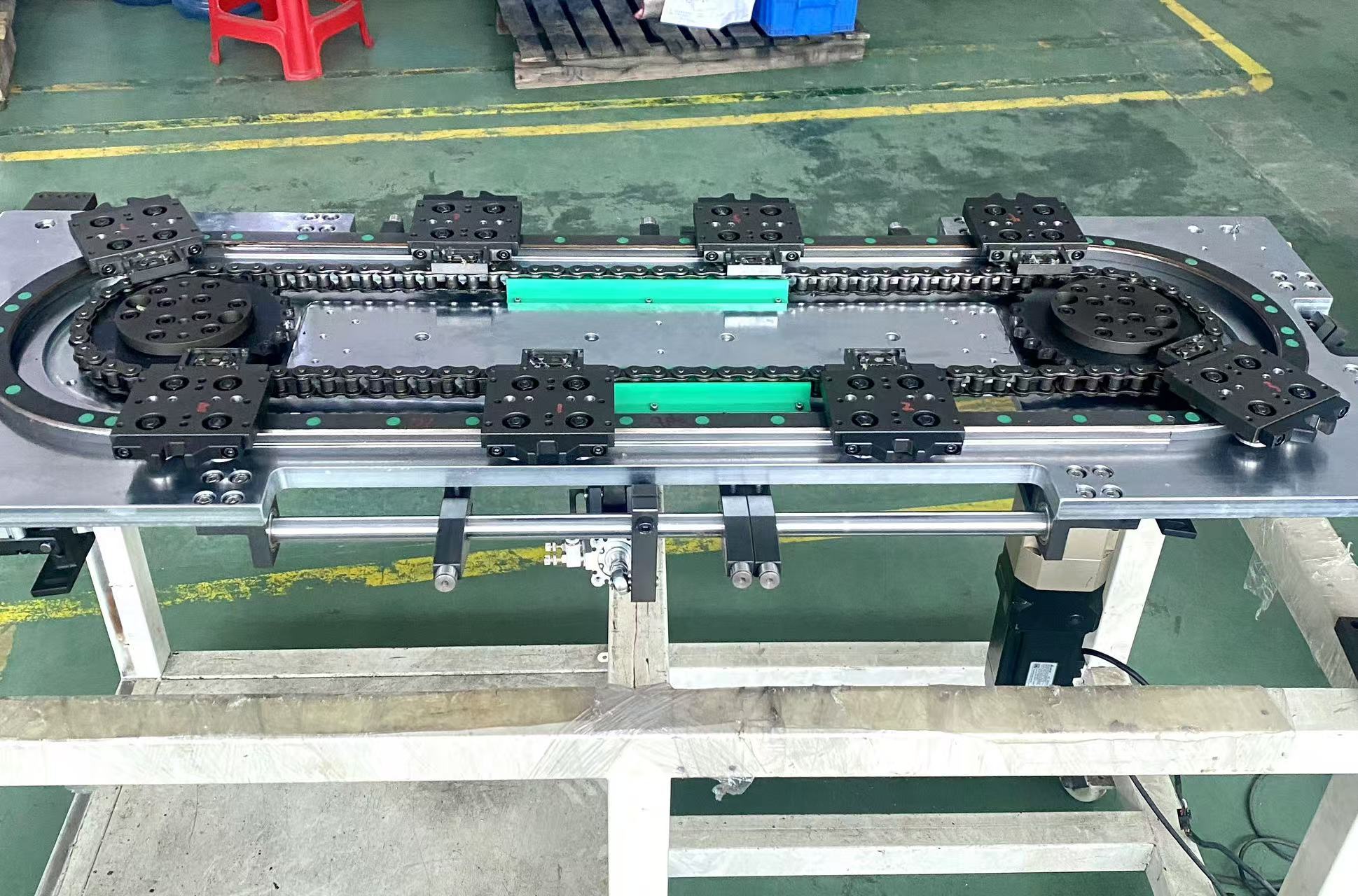

In the realm of industrial equipment and components, particularly within the chain and conveyor systems sector, understanding the mechanics and advantages of rectangle circular conveyors is essential for optimizing operations. These conveyors are a specialized type of transport system designed to move materials and products in a continuous loop. Their unique structure combines the linear features of rectangular conveyors with the efficiency of circular design, making them particularly beneficial in manufacturing and warehousing settings.

One of the primary benefits of rectangle circular conveyors is their ability to maximize space utilization. The rectangular design, while allowing for straight-line transport, seamlessly transitions into circular paths, facilitating efficient handling of materials in congested areas. This adaptability is crucial in environments where floor space is limited, enabling manufacturers to streamline their processes without sacrificing productivity.

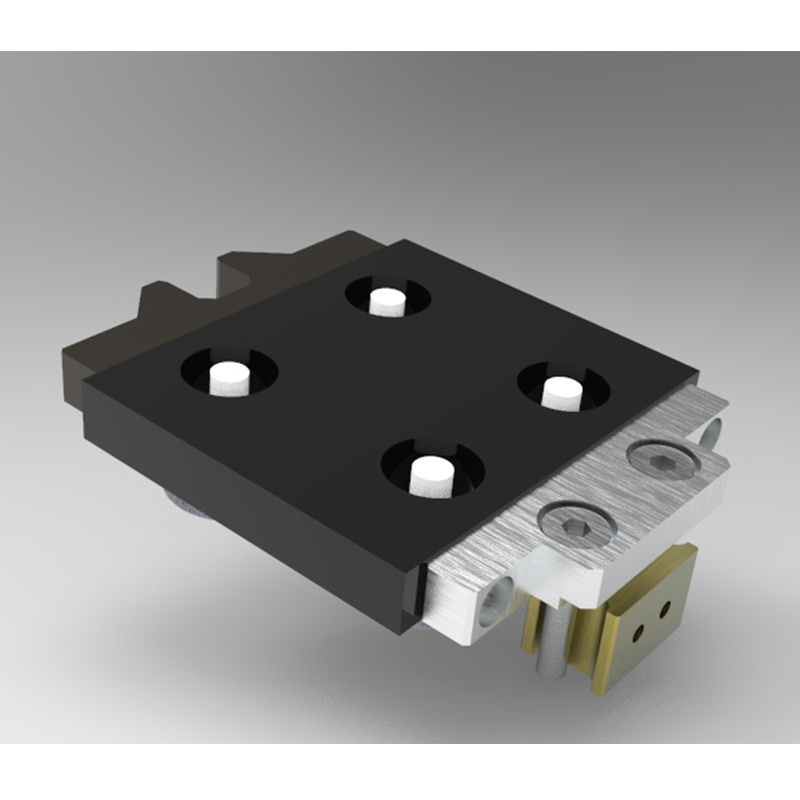

Moreover, these conveyors often include modular components, allowing for easy customization and scalability. This flexibility is particularly advantageous for businesses that may experience fluctuations in production volume or changes in product types. By adjusting the configuration of the rectangle circular conveyor system, companies can respond effectively to varying demands while maintaining consistent throughput.

Another noteworthy aspect of rectangle circular conveyors is their capacity for high-speed operations. The continuous flow nature of these systems reduces downtime and ensures that materials are transported swiftly from one point to another. This efficiency not only enhances productivity but also improves overall operational turnaround times, allowing businesses to meet tight deadlines and fulfill customer orders more effectively.

In addition to speed and space efficiency, rectangle circular conveyors can contribute to improved safety in the workplace. Many modern conveyor systems are designed with safety features, such as emergency stop buttons, guards, and sensors that detect obstructions. These elements help create a safer working environment, reducing the risk of accidents and injuries associated with material handling.

Furthermore, the integration of advanced technology in rectangle circular conveyors allows for the tracking and monitoring of materials in real-time. This capability aids in inventory management and enhances visibility across the supply chain, enabling companies to make informed decisions based on accurate data.

In conclusion, rectangle circular conveyors offer a multitude of advantages for professionals in the industrial equipment sector. Their innovative design, coupled with high efficiency, adaptability, and safety features, makes them an invaluable asset for modern manufacturing and logistics operations. By understanding the importance of these systems, businesses can leverage their potential to enhance productivity and maintain competitiveness in an ever-evolving market.

Hot Tags:

Related News