Oval Circular Conveyors: The Essential Component for Agile Manufacturing Efficiency

Apr 30,2025

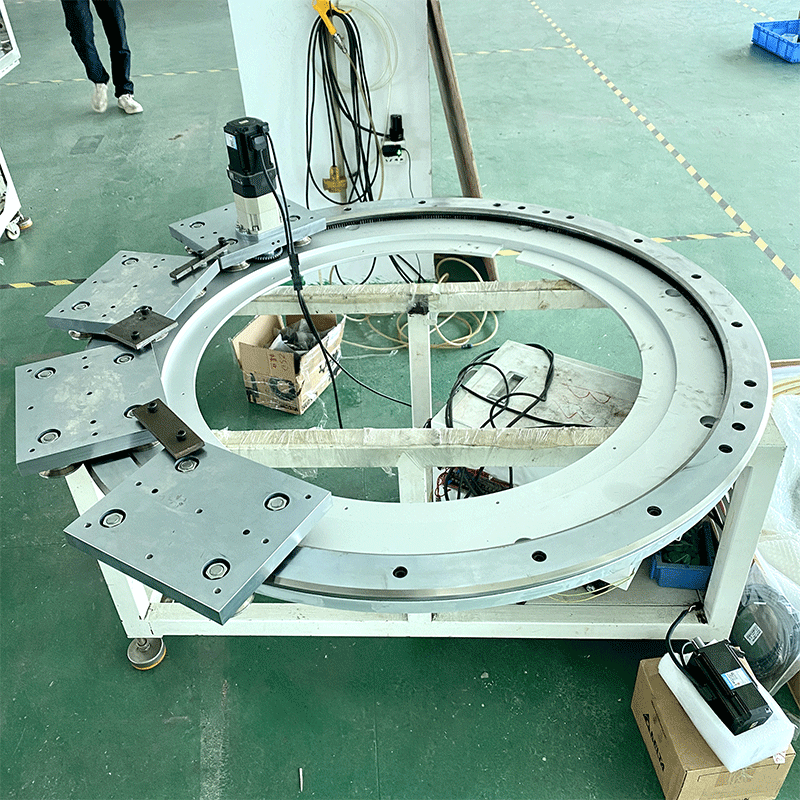

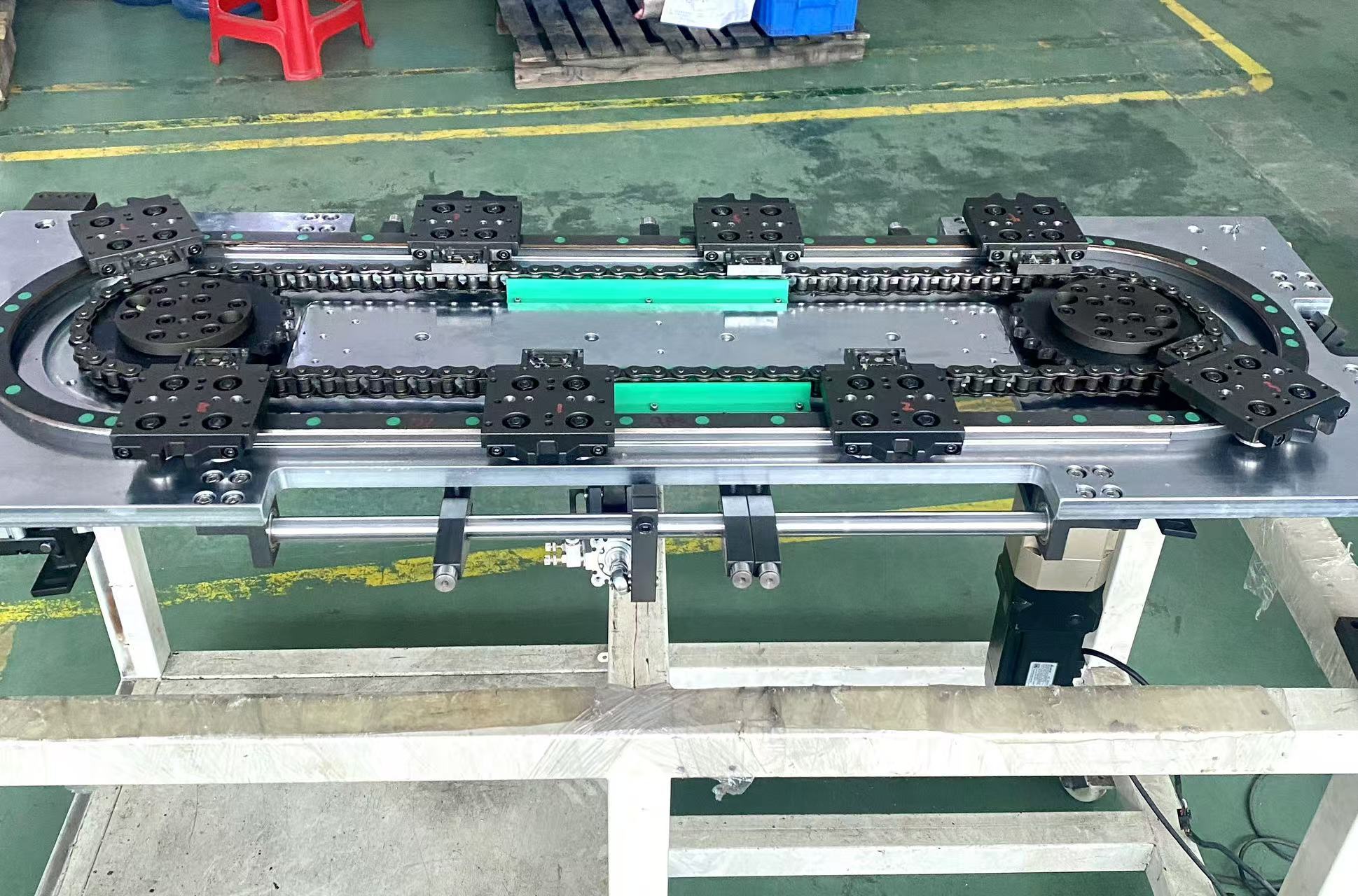

An oval circular conveyor is an advanced material handling system widely used in various industries for its efficiency and versatility. Unlike traditional straight-line or simple circular systems, the oval circular conveyor is designed to offer continuous motion in a compact layout, making it ideal for applications requiring high throughput with limited floor space. This system is often favored in sectors such as automotive manufacturing, electronics assembly, and food processing, where precision and consistency are critical.

One of the defining features of the oval circular conveyor is its ability to seamlessly integrate multiple workstations along its path. The oval shape allows for smooth transitions between linear and curved sections, enabling more ergonomic workflows and better utilization of space. This is especially beneficial in automated environments, where robotic arms and machinery can be positioned optimally around the conveyor's path.

Durability and customization are key advantages of the oval circular conveyor. Depending on the application, the system can be constructed using stainless steel, aluminum, or other corrosion-resistant materials to meet hygiene or heavy-duty requirements. Modular designs also allow users to easily expand, reconfigure, or maintain the conveyor with minimal downtime.

In conclusion, the oval circular conveyor offers a reliable, space-efficient, and adaptable solution for modern production environments. Its unique geometry and continuous loop operation support streamlined workflows, making it a valuable asset for industries aiming to enhance productivity and operational efficiency.

Hot Tags:

Related News