The Importance of Quality Driven Track Systems in Manufacturing

May 26,2025

Track systems serve as a critical foundation for achieving precision in manufacturing environments. These systems are designed to facilitate the smooth movement of machinery components, ensuring that operations occur efficiently and accurately. In the realm of machine tools, track systems are often responsible for guiding tools and parts along predetermined paths, which is vital for maintaining high levels of accuracy and productivity.

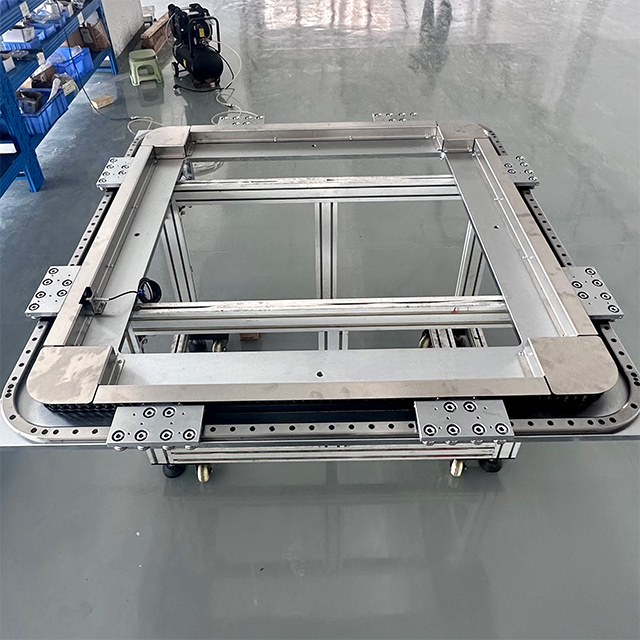

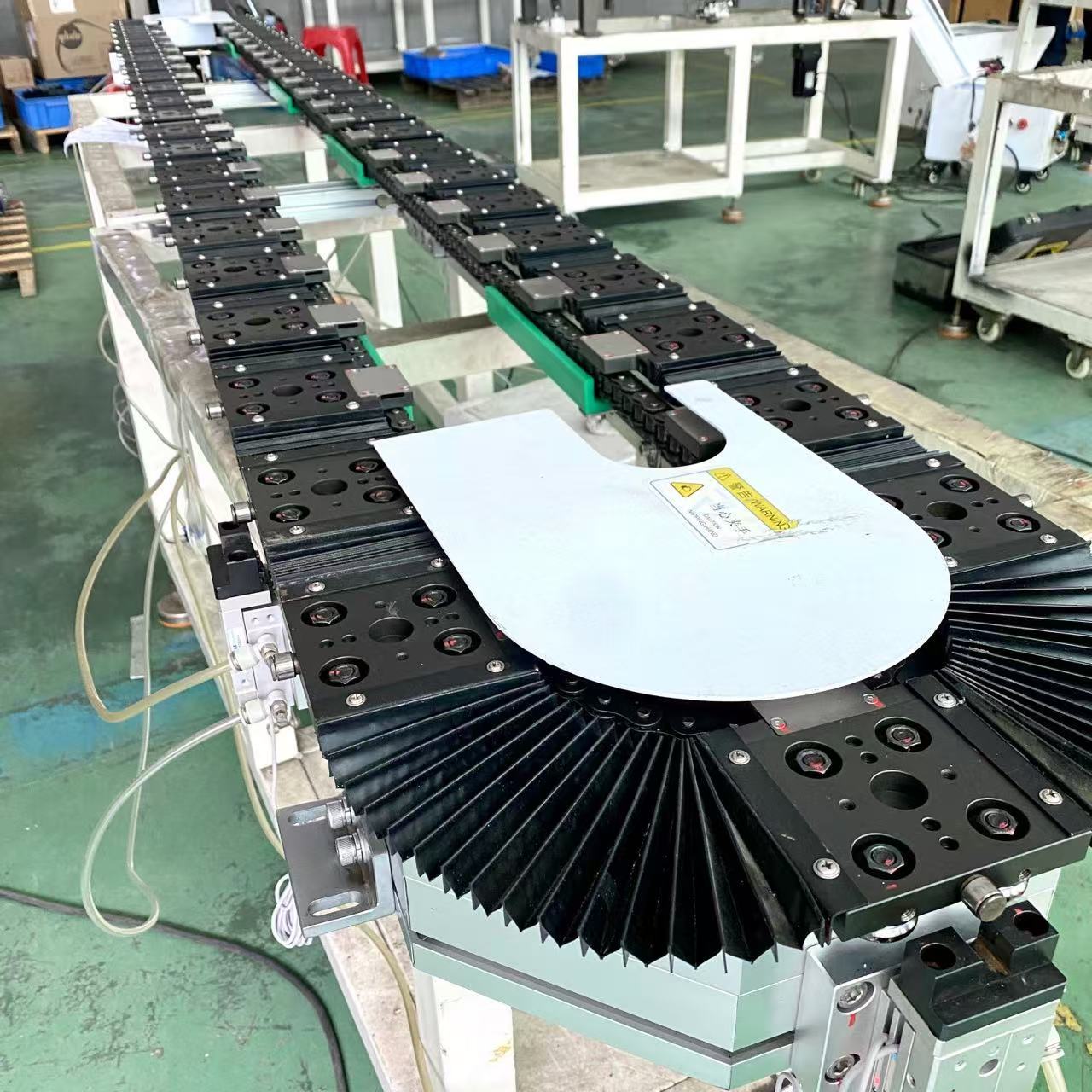

Track systems consist of various components such as rails, bearings, and carriages that work in tandem to allow movement with minimal friction. They are engineered to accommodate different loads, speeds, and environmental conditions, making them versatile for a range of applications in manufacturing and machining.

Precision is paramount in manufacturing, as even the slightest deviation can lead to significant quality issues. Quality-driven track systems play a pivotal role in ensuring that parts are positioned and moved with the utmost accuracy, which directly impacts the overall quality of the finished product.

Rails are the primary components of track systems, providing the pathway for movement. They are typically made from high-strength materials that withstand wear over time. The design of the rail can significantly impact the smoothness of operation, load capacity, and resistance to deformation.

Carriages are responsible for holding and guiding the equipment along the rails. They are often fitted with precision bearings that reduce friction and allow for smooth motion. The design and material of carriages determine how well they distribute load and resist wear.

Bearings minimize friction between moving parts and are crucial for the longevity of track systems. High-quality bearings facilitate smoother movement and provide better shock absorption, which is essential for maintaining precision in operations.

These devices ensure that the track system is securely installed and properly aligned. Misalignment can lead to operational inefficiencies and increased wear. Quality fastening and alignment mechanisms are vital for maintaining the integrity of the track system.

One of the primary benefits of quality track systems is their ability to maintain precision and accuracy. With minimal play between components, these systems ensure that the machinery operates within the required tolerances, leading to higher quality products.

Quality track systems can reduce friction, allowing for faster movement of machine parts. This increased efficiency translates to improved cycle times and productivity, ultimately benefiting the bottom line of manufacturing operations.

High-quality materials and designs in track systems result in a longer service life and lower maintenance requirements. This reduces downtime and associated costs, allowing for more consistent production schedules.

Quality track systems often come with safety features designed to prevent accidents and injuries. By ensuring that machinery operates smoothly and predictably, manufacturers can create a safer work environment for their employees.

In aerospace manufacturing, precision is non-negotiable. Track systems are utilized in CNC machines to ensure that components are manufactured with exact specifications, critical for safety and performance.

Automotive assembly lines rely on quality track systems to move components and tools efficiently. These systems help streamline processes, reduce lead times, and ensure that parts fit together flawlessly.

In the production of medical devices, track systems play a crucial role in ensuring that parts are assembled accurately and consistently. This precision is vital for compliance with industry regulations and safety standards.

The electronics industry requires highly precise operations for the installation of components on printed circuit boards (PCBs). Track systems enable the accurate movement of machinery to adhere to tight tolerances.

Routine inspections can identify wear and damage early, preventing costly repairs down the line. Check for signs of misalignment, wear on rails, and any obstruction that can hinder movement.

Applying appropriate lubricants to bearings and moving parts reduces friction and prolongs the lifespan of the track system. Ensure that lubrication is done regularly as part of the maintenance schedule.

Keep the track system clean and free of debris. Dust and contaminants can affect the performance and accuracy of the system. Use appropriate cleaning solutions and tools to maintain cleanliness.

Consider the speed at which the machinery needs to operate. High-speed applications may require specialized track systems that can handle rapid movements without compromising precision.

The integration of smart technology into track systems allows for real-time monitoring and adjustments. This technology can enhance precision and efficiency by providing data-driven insights.

Innovations in materials science are leading to the development of lighter and stronger materials for track systems. These advancements promise to improve performance while reducing overall weight.

With the rise of automation and robotics in manufacturing, track systems are becoming increasingly sophisticated. Automated systems can enhance precision and efficiency, leading to better production outcomes.

As industries shift towards more sustainable practices, track system manufacturers are focusing on eco-friendly materials and production methods. This trend is likely to shape the future landscape of manufacturing equipment.

Quality-driven track systems are essential for achieving precision and efficiency in manufacturing. Their components, benefits, and applications highlight their importance across various industries. By investing in high-quality systems and adhering to proper maintenance practices, manufacturers can unlock the full potential of their operations. As technology continues to evolve, staying abreast of trends will ensure that businesses remain competitive in an ever-changing landscape.

Hot Tags:

Related News