Understanding Circular Rail Conveyors: Enhancing Efficiency in Industrial Operations

Jun 30,2025

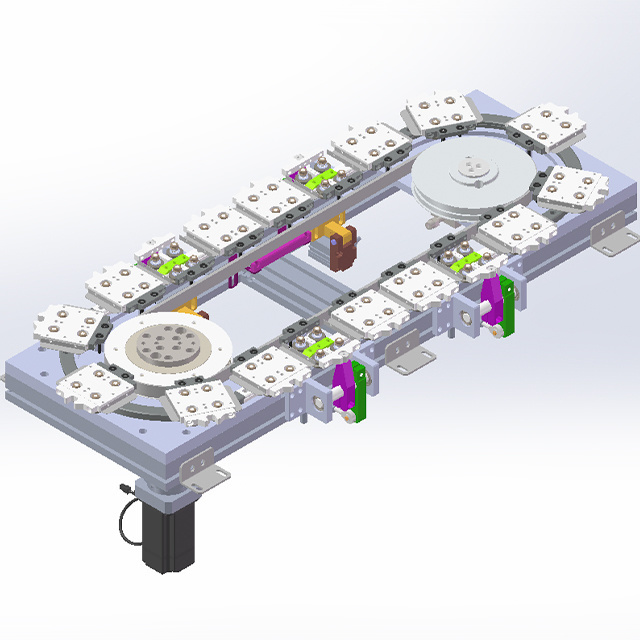

In the realm of industrial equipment and components, circular rail conveyors serve as a crucial element in enhancing the efficiency of material handling processes. These innovative systems are designed to facilitate the seamless movement of products along a predetermined circular path, making them particularly useful in various manufacturing and assembly operations.

One of the primary benefits of circular rail conveyors is their ability to maximize space utilization. Unlike linear conveyor systems, which require more linear space to transport materials, circular rail conveyors can operate within a compact footprint. This makes them ideal for environments where space is limited, allowing manufacturers to maintain high productivity levels without sacrificing valuable floor area.

Another significant advantage lies in their continuous operation capability. Circular rail conveyors are designed to operate seamlessly, enabling the uninterrupted flow of goods. This is particularly beneficial in high-demand environments where consistent throughput is essential. By using a circular configuration, these conveyors can efficiently manage the flow of products from one point to another, reducing bottlenecks and enhancing overall productivity.

Moreover, circular rail conveyors can be integrated with various accessories and components, such as automated loading and unloading systems, which further streamline operations. These systems can be customized to accommodate specific product types and handling requirements, ensuring that they meet the diverse needs of different industries. Whether it's handling delicate components or transporting heavy materials, circular rail conveyors can be tailored to suit various applications.

In addition to their operational benefits, circular rail conveyors are also designed with durability and maintenance in mind. Many systems are constructed from robust materials that withstand the rigors of industrial environments, thereby reducing downtime due to wear and tear. Regular maintenance practices can further prolong the lifespan of these conveyors, ensuring they remain a reliable asset to any production line.

When considering the integration of a circular rail conveyor into your operations, it's essential to assess your specific material handling needs. Factors such as the type of products being transported, the required speed of operation, and available space will all influence the design and configuration of the conveyor system. Working with industry experts can help you identify the most effective solution tailored to your operational requirements.

In conclusion, circular rail conveyors represent a powerful tool for enhancing efficiency in industrial operations. Their compact design, continuous operation, and adaptability to various applications make them an attractive choice for many businesses. By understanding their functionalities and benefits, professionals in the industrial equipment sector can make informed decisions that contribute to streamlined processes and improved productivity.

Hot Tags:

Related News