Elevate Your Machinery with Quality Driven Track Systems: A Comprehensive Guide

Jul 05,2025

Elevate Your Machinery with Quality Driven Track Systems

Table of Contents

1. Introduction to Track Systems in Machinery

2. Understanding the Importance of Quality in Track Systems

3. Types of Track Systems for Machinery

3.1 Linear Guide Rails

3.2 Ball Transfer Units

3.3 Roller Tracks

4. Benefits of Quality Driven Track Systems

4.1 Enhanced Precision and Accuracy

4.2 Increased Durability and Longe

Elevate Your Machinery with Quality Driven Track Systems

Table of Contents

1. Introduction to Track Systems in Machinery

2. Understanding the Importance of Quality in Track Systems

3. Types of Track Systems for Machinery

3.1 Linear Guide Rails

3.2 Ball Transfer Units

3.3 Roller Tracks

4. Benefits of Quality Driven Track Systems

4.1 Enhanced Precision and Accuracy

4.2 Increased Durability and Longevity

4.3 Improved Operational Efficiency

5. Key Features to Look for in Track Systems

5.1 Material Quality and Construction

5.2 Load Capacity and Weight Distribution

6. Maintenance Tips for Track Systems

7. Common Issues with Track Systems and Their Solutions

8. Conclusion

9. Frequently Asked Questions (FAQs)

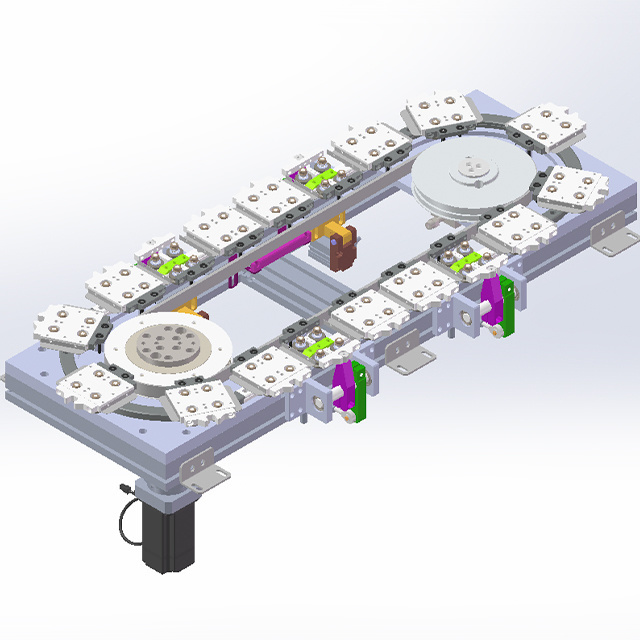

1. Introduction to Track Systems in Machinery

In the competitive landscape of manufacturing, having the right machinery is essential for achieving operational excellence. **Track systems** play a crucial role in ensuring that machinery functions smoothly and efficiently. These systems consist of various mechanical components designed to facilitate the movement and positioning of machinery parts. By elevating the quality of your track systems, you can significantly enhance the performance of your manufacturing equipment.

2. Understanding the Importance of Quality in Track Systems

Quality is paramount when it comes to track systems. A well-constructed track system not only improves the functionality of machinery but also minimizes downtime and maintenance costs. Investing in high-quality track systems can lead to better product output and adherence to project timelines. Furthermore, **quality-driven designs** offer enhanced reliability, which is critical in high-stakes manufacturing environments.

3. Types of Track Systems for Machinery

When selecting track systems for your machinery, it is essential to understand the different types available. Each type offers unique features and benefits, catering to various industrial applications.

3.1 Linear Guide Rails

Linear guide rails are pivotal in applications where precision movement is required. These rails provide smooth and accurate linear motion, making them ideal for CNC machines and assembly lines. Their design allows for easy integration with other machinery components.

3.2 Ball Transfer Units

Ball transfer units are used to facilitate the movement of heavy loads in all directions. They are commonly found in conveyor systems and workstations, allowing operators to move items effortlessly. Their versatility makes them indispensable in modern manufacturing setups.

3.3 Roller Tracks

Roller tracks provide a robust solution for heavy-duty applications. They are designed to handle significant weight and offer smooth movement across the track. Ideal for applications requiring high load capacities, roller tracks enhance workflow efficiency.

4. Benefits of Quality Driven Track Systems

Investing in quality track systems provides numerous advantages that can transform your manufacturing operations.

4.1 Enhanced Precision and Accuracy

Quality track systems ensure that machinery operates with high precision, leading to better product quality. Accurate movements reduce the risk of errors, ensuring that each product meets your specifications.

4.2 Increased Durability and Longevity

High-quality materials and engineering in track systems result in enhanced durability. These systems can withstand harsh working conditions, reducing the frequency of replacements and repairs.

4.3 Improved Operational Efficiency

Efficiency is a critical factor in manufacturing. Quality-driven track systems minimize friction and allow for smoother movements, thus improving the overall productivity of your operations.

5. Key Features to Look for in Track Systems

When selecting track systems, several features can significantly impact your choice. Understanding these features will help you make an informed decision.

5.1 Material Quality and Construction

The materials used in the construction of track systems are vital. High-grade steel or aluminum provides strength and resilience, while rust-resistant coatings extend the lifespan of the system.

5.2 Load Capacity and Weight Distribution

Evaluating the load capacity of track systems is essential to ensure they meet your operational demands. An effective weight distribution mechanism prevents premature wear and tear, prolonging the system's life.

6. Maintenance Tips for Track Systems

Regular maintenance is key to maximizing the lifespan and performance of your track systems. Here are some essential maintenance tips:

1. **Regular Inspections**: Frequent checks for wear and tear help identify potential issues before they escalate.

2. **Lubrication**: Proper lubrication reduces friction, enhancing movement and extending the life of the system.

3. **Cleaning**: Keeping the track system clean from debris and dust prevents damage and promotes smooth operation.

7. Common Issues with Track Systems and Their Solutions

Despite their robustness, track systems can face various challenges. Here are some common issues and their respective solutions:

1. **Noise During Operation**: This could indicate inadequate lubrication or the need for component replacement. Regular maintenance checks can help.

2. **Sticking or Jamming**: Accumulated debris or misalignment can cause this issue. Cleaning and realigning components can resolve it.

3. **Excessive Wear**: This may result from overload or low-quality materials. Assessing load capacity and investing in higher quality components can mitigate this risk.

8. Conclusion

Investing in quality-driven track systems can significantly elevate the performance of your machinery. By understanding the types, benefits, and maintenance practices associated with track systems, you can enhance operational efficiency and product quality in your manufacturing processes. Emphasizing quality not only leads to better performance but also contributes to long-term savings and reliability in your operations.

9. Frequently Asked Questions (FAQs)

What are track systems in machinery?

Track systems are mechanical components designed to facilitate the movement and positioning of machinery parts, enhancing operational efficiency.

Why is quality important in track systems?

Quality ensures reliability, durability, and accuracy in machinery operations, leading to reduced downtime and maintenance costs.

What types of track systems are available?

Common types include linear guide rails, ball transfer units, and roller tracks, each serving unique industrial applications.

How can I maintain my track systems effectively?

Regular inspections, lubrication, and cleaning are essential maintenance practices to ensure the longevity and performance of track systems.

What problems can arise with track systems?

Common issues include noise during operation, sticking or jamming, and excessive wear, each manageable with proper maintenance and quality components.

By focusing on these elements, you can elevate your machinery's performance and achieve operational excellence through quality-driven track systems.

Hot Tags:

Related News