The Critical Importance of Quality Driven Track Systems in Modern Machining

Jul 25,2025

Track systems serve as the backbone of various machining operations. They are designed to facilitate the smooth movement of machinery, tools, and components within manufacturing processes. By providing a stable and precise path for motion, track systems ensure that machines operate efficiently, which is vital in achieving high production standards.

The underlying principle of track systems is to minimize friction and wear, allowing components to glide seamlessly. This is particularly important in environments where precision is paramount, as any deviation in movement can lead to defects in the final product.

Quality is a decisive factor in the performance of track systems. A well-crafted track system can significantly reduce downtime, extend equipment life, and enhance overall machining accuracy. High-quality materials, precise manufacturing techniques, and stringent testing protocols contribute to the robustness of track systems.

When selecting track systems, manufacturers should prioritize those that meet international quality standards. This commitment to quality not only ensures optimal performance but also fosters trust among clients who rely on the precision of the machinery.

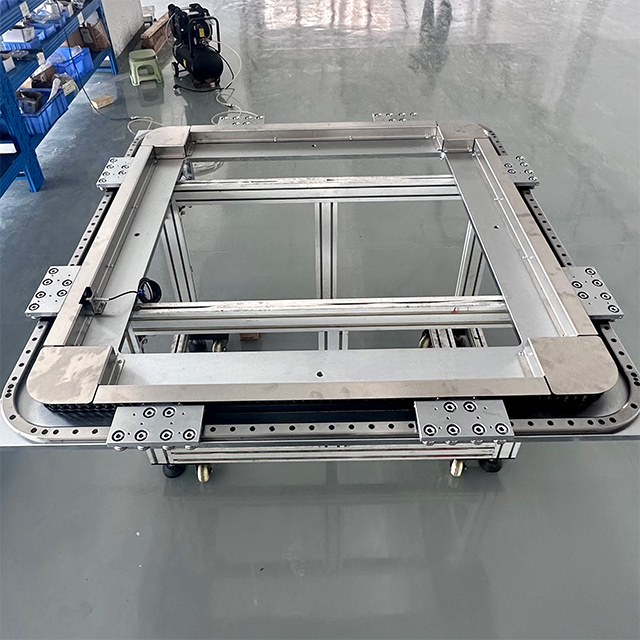

Linear guide systems are widely used in machining for their ability to provide smooth and precise linear motion. They consist of a rail and a sliding block that moves along the rail, ensuring minimal friction and high load-bearing capabilities. These systems are particularly effective in CNC machines and robotic applications where precision is paramount.

Ball rail systems incorporate ball bearings within their design, allowing for smooth movement along the rail. This type of track system is known for its high load capacity and low friction, making it ideal for heavy machinery and high-speed applications. Ball rail systems are extensively used in various industries, including automotive and aerospace, where precision and reliability are critical.

Roller guide systems utilize cylindrical rollers to facilitate movement along the track. This design minimizes wear and friction while supporting heavy loads. Roller guide systems are often deployed in applications requiring high rigidity and durability, such as in metalworking and fabricating machinery.

Quality track systems enhance the precision and accuracy of machining processes. By providing a stable movement platform, they minimize deviations and errors in production, ultimately leading to higher-quality end products.

Investing in high-quality track systems results in increased durability. These systems are engineered to withstand wear and tear, reducing the frequency and cost of replacements. Enhanced durability translates to lower maintenance costs and less downtime.

With quality track systems in place, machines can operate at higher speeds and with greater efficiency. This boost in productivity not only leads to increased output but also optimizes resource usage, contributing to overall cost savings for manufacturers.

The machining industry is continuously evolving, and so are track systems. Recent innovations include intelligent tracking systems that integrate sensors and automation technologies, allowing for real-time monitoring and performance optimization. These advancements enable manufacturers to predict maintenance needs and improve operational efficiency.

Furthermore, the development of lightweight materials and advanced coatings has enhanced the performance and longevity of track systems, making them suitable for a wider range of applications.

While the benefits of quality-driven track systems are clear, there are challenges in their implementation. One common issue is the initial cost associated with high-quality systems. However, the long-term savings in maintenance and operational costs often outweigh this initial investment.

Another challenge is ensuring proper alignment and installation. Incorrect installation can lead to premature wear and failure. To mitigate this, manufacturers should invest in training for their staff and consider hiring specialists for installation.

Hot Tags:

Related News