Everything You Need to Know About Customized Ring Guide Tracks

Jul 15,2025

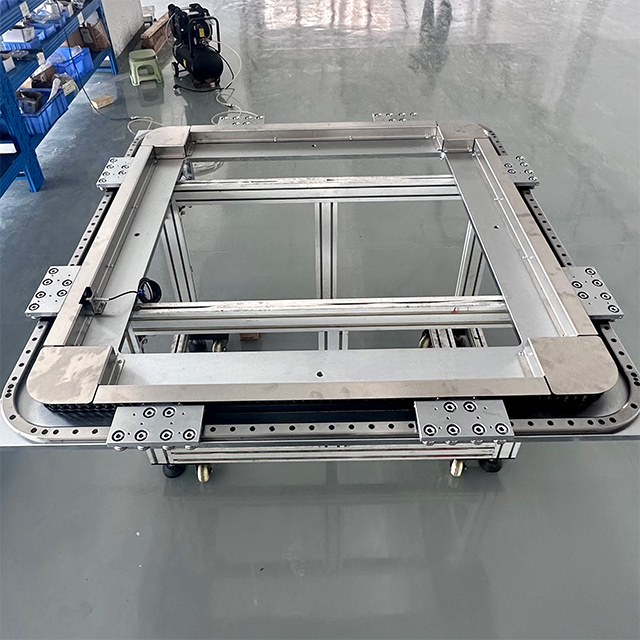

Customized ring guide tracks are precision-engineered components used in various manufacturing and automation applications. Designed to provide smooth linear motion and support heavy loads, these tracks are critical in ensuring the efficiency and accuracy of machines. They typically consist of a guiding mechanism that allows for seamless movement, which is particularly essential in CNC machines, robotic arms, and other automated systems.

The design of ring guide tracks allows them to accommodate rotational as well as linear motions, offering versatile solutions for complex machinery setups. Their customization options enable businesses to tailor dimensions, load capacities, and other specifications to meet specific operational needs.

Customized ring guide tracks are tailored to ensure optimal functionality with minimal friction, leading to smoother operations. This efficiency translates to faster production rates and reduced energy consumption.

With custom designs, engineers can create tracks that evenly distribute weight and absorb vibrations effectively. This stability is crucial for maintaining precision in high-speed or heavy-load applications.

Though initial investment costs may be higher for customized tracks, the long-term benefits of reduced downtime and maintenance costs often outweigh these expenses. A tailored solution can significantly decrease the total cost of ownership.

Businesses can incorporate unique features or modifications that align with their specific operational requirements, making the machinery more adaptable to changing production needs.

In CNC machines, ring guide tracks play a crucial role in ensuring accurate and smooth tool movements. Customization allows for tracks that accommodate specific machining processes and materials.

Robotic arms often require complex movements. Customized ring guide tracks provide the precision needed for intricate tasks in assembly lines, packaging, and material handling.

Customized ring guide tracks are vital components in various manufacturing processes, enhancing efficiency, stability, and safety. Their tailored designs cater to unique operational requirements, making them indispensable in modern manufacturing. By understanding the benefits, materials, applications, and maintenance of these tracks, businesses can optimize their machinery for better performance and longevity. Investing in customized solutions is a strategic move that pays dividends in productivity and cost savings, ensuring that machinery operates at peak efficiency for years to come.

Hot Tags:

Related News