The Benefits of Circular Rail Conveyors in Industrial Settings

Jul 20,2025

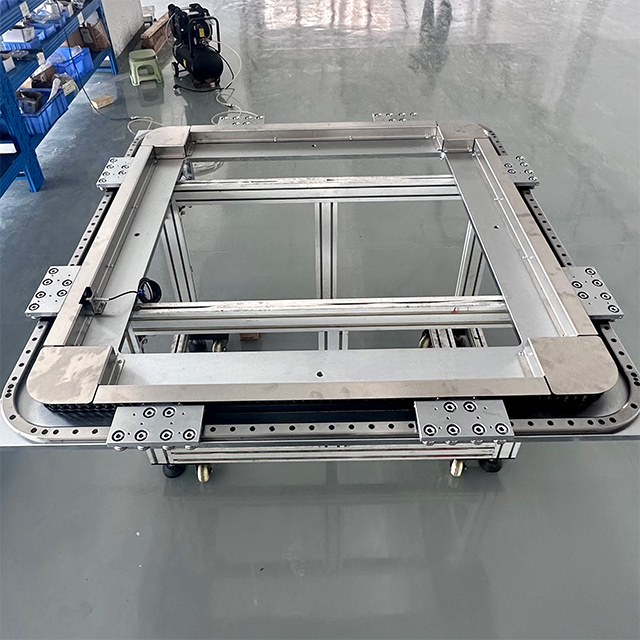

Circular rail conveyors are an essential component in the field of industrial equipment and components, particularly within the realm of conveying systems. These systems are designed to improve material handling efficiency in a range of manufacturing and storage applications. By utilizing a circular rail design, these conveyors allow for the continuous movement of goods, which can significantly enhance workflow and productivity.

One of the primary advantages of circular rail conveyors is their ability to facilitate a streamlined process. Unlike traditional linear conveyors, circular systems can transport materials in a continuous loop, minimizing the need for manual intervention. This design not only reduces the risk of downtime but also optimizes space, making it ideal for facilities with limited floor area. The circular layout allows products to be delivered to various stations, such as assembly lines or packing areas, without the need for complex routing.

Another critical feature of circular rail conveyors is their adaptability. These systems can be customized to accommodate different product types, sizes, and weights. Whether you are handling small components or larger items, a circular rail conveyor can be tailored to meet specific operational requirements. This flexibility is particularly beneficial in industries such as automotive, electronics, and food processing, where diverse product lines are common.

Durability and reliability are also key benefits associated with circular rail conveyors. Constructed from high-quality materials, these systems are designed to withstand the rigors of industrial environments. They can operate effectively in high-speed applications, ensuring that production schedules are maintained without compromising on performance. Additionally, advanced engineering techniques allow for smoother operation, reducing wear and tear on both the conveyor system and the transported materials.

Maintenance is another area where circular rail conveyors shine. Many modern systems are designed with ease of maintenance in mind, featuring accessible components that simplify routine inspections and repairs. This can lead to increased uptime and lower operational costs, as companies can proactively address any issues before they become significant problems.

In summary, circular rail conveyors represent a vital innovation in the field of industrial equipment and components. Their ability to enhance efficiency, adaptability, durability, and ease of maintenance makes them an invaluable asset for businesses looking to optimize their material handling processes. By integrating circular rail conveyors into your operations, you can improve workflow, reduce labor costs, and ultimately drive greater productivity. Embracing this technology could be the key to staying competitive in today's fast-paced industrial landscape.

Hot Tags:

Related News