Customizing Guide Tracks

Aug 04,2025

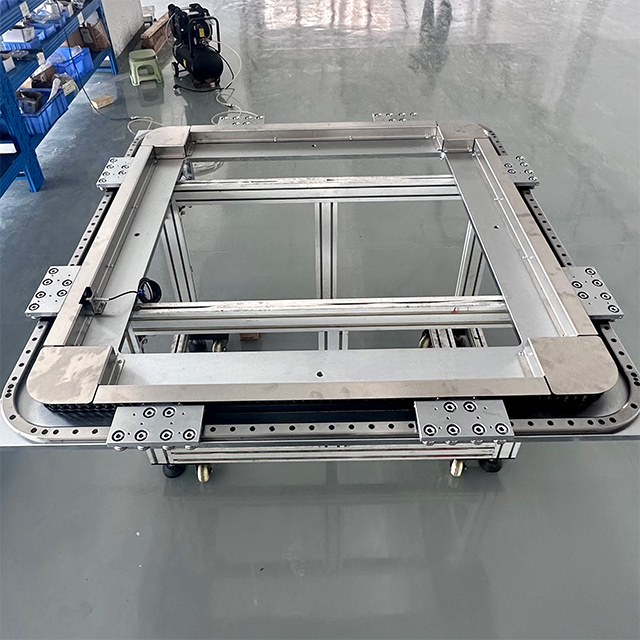

Customizing guide tracks is crucial for optimizing the performance of your machinery. Standard tracks may not always meet the unique demands of specific applications. Customization allows for the adjustment of dimensions, materials, and surface finishes to improve durability, performance, and compatibility with different machining environments.

Identify the specific needs of your machining application. Are you working with heavy loads, high speeds, or specific environmental conditions? Understanding these requirements will guide your customization choices.

Begin by evaluating your existing guide tracks. Identify any limitations or issues affecting performance. This assessment will help you determine the necessary modifications for improvement.

Based on your assessment, define the specifications for your custom guide tracks. Consider dimensions, load capacity, and material preferences. Document these specifications clearly to communicate your needs effectively.

Engage with manufacturers or engineers who specialize in custom machining components. Provide them with your specifications and application requirements. Their expertise will be invaluable in recommending the best solutions.

Before committing to full-scale production, request prototypes of your customized guide tracks. Testing prototypes will allow you to evaluate performance and make necessary adjustments before finalizing your designs.

Implement a quality control process to ensure that the final product meets your specified requirements. This might include dimensional checks, material testing, and performance evaluations.

Once your custom guide tracks are produced, install them in your machinery. Conduct thorough testing to verify that they perform as expected. Monitor for any irregularities and make adjustments as necessary.

Customizing guide tracks is a critical step in optimizing the performance of manufacturing machinery. By following a structured approach and considering factors such as application requirements, material selection, and surface finishes, you can achieve superior results tailored to your specific needs. Regular maintenance and inspections will ensure that your customized guide tracks continue to perform at their best, contributing to the overall efficiency and accuracy of your machining operations. Embrace the possibilities of customization to unlock your machinery's full potential.

Hot Tags:

Related News