Revolutionize Your Machinery with Tailored Ring Guide Tracks

Jun 25,2025

In the realm of manufacturing and machining, precision is paramount. The efficiency and effectiveness of machine tools largely depend on the components that facilitate their operation. One such vital component is the ring guide track. These specialized tracks are designed to provide smooth linear motion, enhancing the performance of various machinery. In this article, we will explore how tailored ring guide tracks can revolutionize your machinery, ensuring improved accuracy and efficiency.

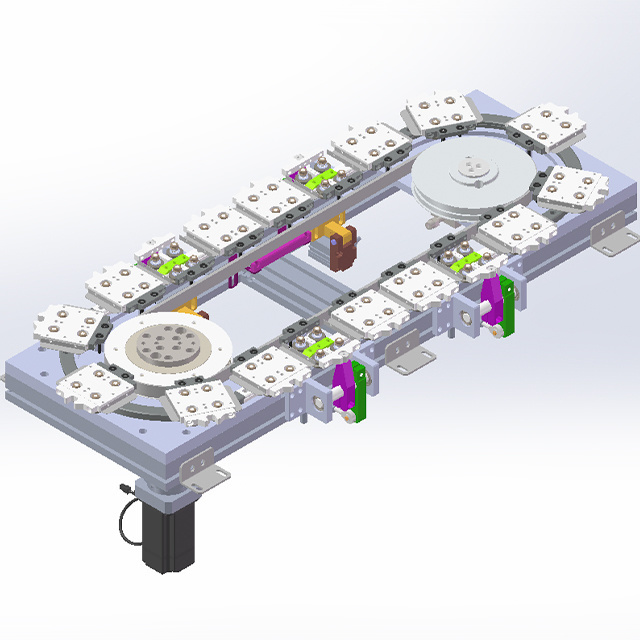

Ring guide tracks are linear motion systems that allow for the smooth movement of machinery components. They serve as a guiding mechanism for moving parts, ensuring that they operate with minimal friction and wear. Typically made from high-quality materials, these tracks can be customized to meet specific operational needs.

Every manufacturing process is unique, and a one-size-fits-all approach often leads to inefficiencies. Tailoring your ring guide tracks to fit your specific machinery needs ensures optimal performance. This customization can involve adjusting dimensions, materials, and configurations to better suit individual applications.

Precision is critical in machining operations where even minor deviations can lead to defects. Tailored ring guide tracks ensure that components move seamlessly, maintaining alignment and reducing the likelihood of errors.

Using high-quality materials tailored to the specific application not only improves performance but also extends the lifespan of the machinery. Custom ring guide tracks can withstand varying loads and environmental conditions, providing consistent performance over time.

When machinery operates smoothly, productivity naturally improves. Tailored ring guide tracks minimize friction and resistance, allowing for faster operation without sacrificing precision. This increase in efficiency ensures more output in less time.

Investing in tailored ring guide tracks may seem like a significant upfront cost, but the long-term savings from reduced wear, lower maintenance, and increased productivity make it a worthwhile investment.

Begin by evaluating your existing machinery and identifying areas where improvements can be made. Understanding the specific requirements of your machines will help determine the best customization options.

Work with manufacturers who specialize in tailored ring guide tracks. Their expertise can guide you in selecting the appropriate materials, dimensions, and configurations to meet your needs.

Before fully integrating a new ring guide track system, create prototypes and conduct rigorous testing. This step ensures that the tailored solution meets performance expectations without compromising machinery integrity.

In summary, tailored ring guide tracks offer a transformative solution for enhancing the performance of machinery in manufacturing and machining industries. By providing improved precision, efficiency, and durability, these innovative components can lead to significant long-term savings and productivity gains. Investing in tailored solutions not only optimizes your current operations but also positions your business for future advancements. Embrace the potential of tailored ring guide tracks and witness a revolution in your machinery’s capabilities.

Hot Tags:

Related News