Understanding the Benefits of China Circular Conveyor Lines in Manufacturing

Jun 20,2025

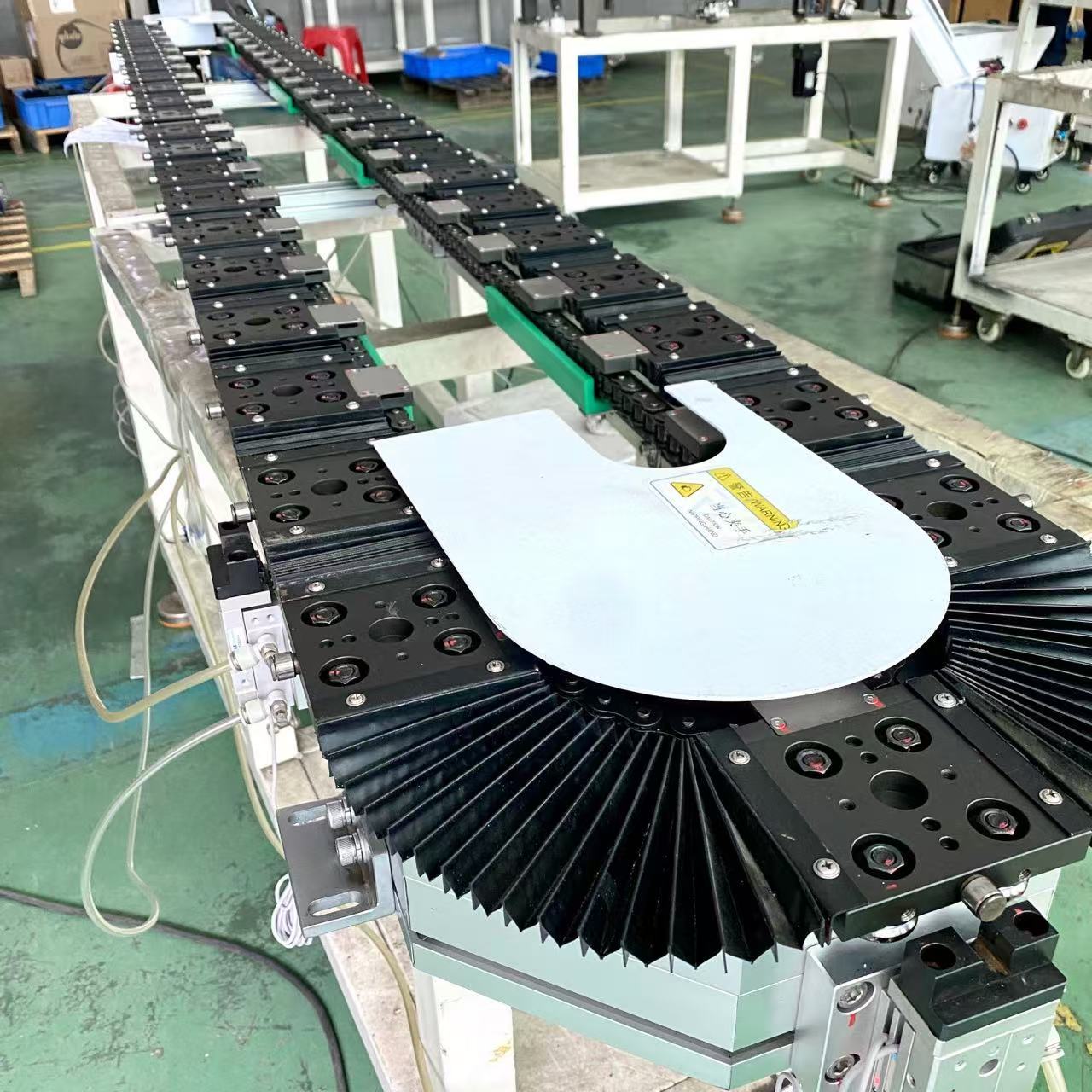

In the manufacturing sector, particularly within the realm of machining and machine tool accessories, the implementation of efficient logistics and handling systems is crucial. One such system gaining traction is the China Circular Conveyor Line. This innovative solution is designed to facilitate the smooth and continuous transportation of materials through various stages of production, ultimately leading to enhanced productivity and operational efficiency.

A circular conveyor line operates on a straightforward yet effective principle: it utilizes a looped pathway that allows for the seamless movement of items. This design minimizes interruptions in the workflow, ensuring that materials are consistently fed into production processes without the delays associated with traditional conveyor systems. The efficiency of a circular conveyor line makes it especially beneficial for industries dealing with high volumes of components, such as machine tool accessory manufacturing.

One significant advantage of using China Circular Conveyor Lines is their versatility. These systems can be integrated with various types of machinery and production setups, making them adaptable to specific manufacturing requirements. This flexibility is particularly advantageous for businesses that produce a diverse range of products or frequently change their production line configurations.

In addition to their adaptability, circular conveyor lines also enhance safety in the workplace. By providing a designated pathway for materials, they reduce the risk of accidents associated with manual handling. Workers can focus more on their tasks rather than navigating around cluttered workspaces, which can lead to injuries or inefficiencies. This increased safety not only protects employees but also minimizes downtime, contributing to overall productivity.

Moreover, these conveyor systems can significantly reduce labor costs. With automation playing a growing role in manufacturing, circular conveyor lines can be programmed to operate with minimal human intervention. This shift not only streamlines production processes but also allows businesses to allocate their workforce to more skilled tasks, optimizing labor resources.

Another factor to consider is the energy efficiency of circular conveyor lines. Many modern systems are designed with energy-saving features that contribute to reduced operational costs. This focus on sustainability aligns with the growing trend towards environmentally responsible manufacturing practices. By implementing energy-efficient solutions, businesses can reduce their carbon footprint while also benefiting from cost savings.

In conclusion, China Circular Conveyor Lines represent a transformative advancement in manufacturing logistics. Their ability to enhance efficiency, safety, and adaptability makes them a valuable asset for companies in the machining and machine tool accessories industry. As the manufacturing landscape continues to evolve, embracing innovative solutions like circular conveyor lines will be essential for maintaining a competitive edge and driving future success.

Hot Tags:

Related News