Unlocking Precision: Your Ultimate Guide to Customize Ring Track Systems

Jun 05,2025

Ring track systems have revolutionized the way precision engineering is approached in various industries. These systems offer a unique blend of flexibility, customization, and efficiency, making them ideal for a multitude of applications. Whether you are in manufacturing, assembly, or any process that requires high precision, understanding ring track systems is essential for optimizing your operations.

Customization has become a crucial aspect of modern manufacturing. Off-the-shelf solutions often fail to meet the specific needs of individual businesses, leading to inefficiencies and increased operational costs. Customizable ring track systems address these challenges head-on. By tailoring these systems to fit your unique requirements, you enhance productivity, reduce waste, and improve overall operational efficiency.

Customizing your ring track system allows you to design it specifically for your workflow, enabling smoother operations and less downtime. By eliminating bottlenecks, you can achieve higher output and better utilize your resources.

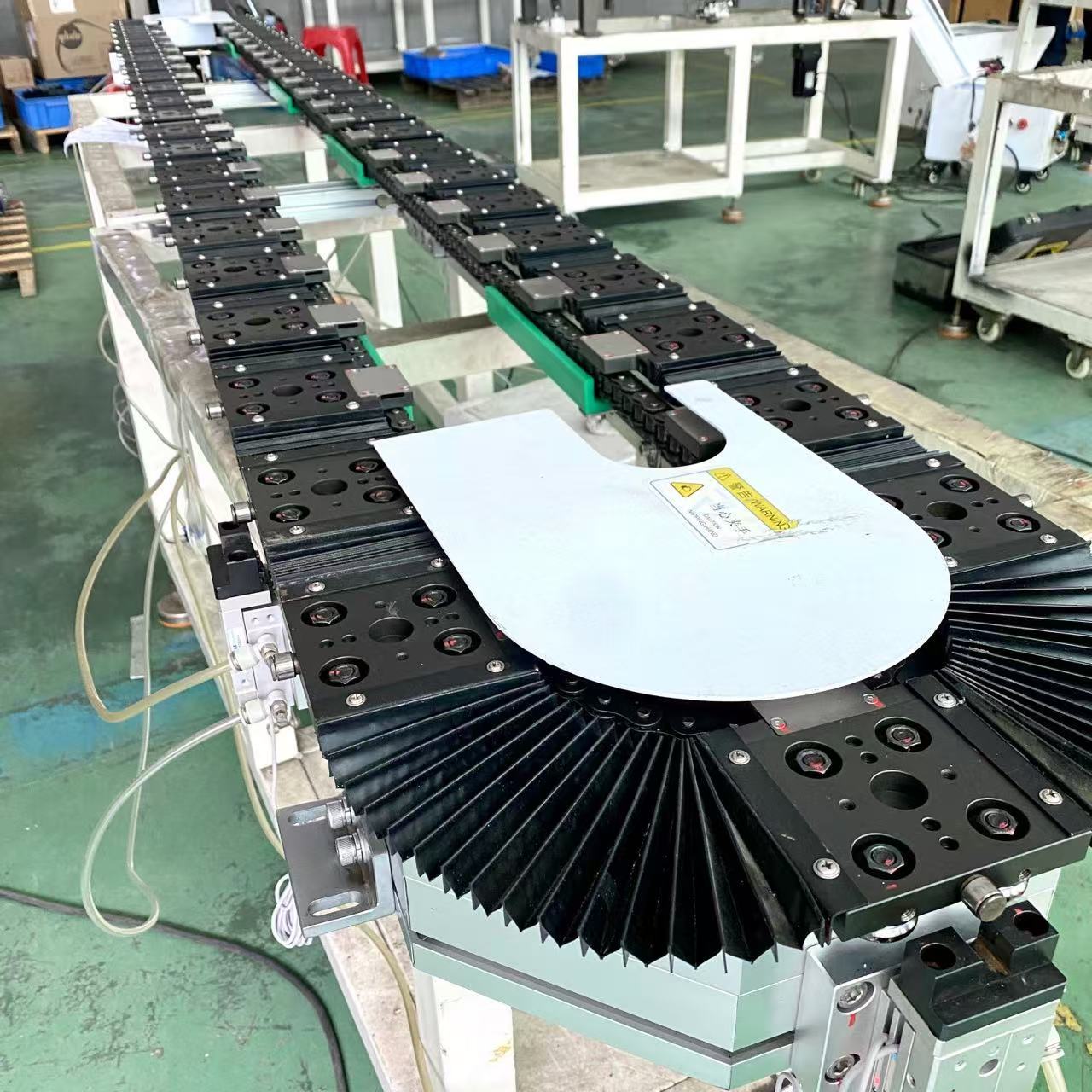

A ring track system is composed of several integral components that work together to deliver precision and efficiency. Understanding these components is essential when considering customization.

The rails form the backbone of the ring track system. They can be made of various materials depending on the required load capacity and application. The choice of rail material directly impacts durability and performance.

Drives control the movement along the rails. Depending on the application, different types of drives, such as electric, pneumatic, or hydraulic, can be employed to achieve the desired speed and torque.

Carriages facilitate smooth movement along the rails. The design of the carriages can be customized to accommodate specific load requirements and motion profiles, ensuring optimal performance in your applications.

Various accessories, such as sensors and brackets, can be integrated into the ring track system to enhance functionality and provide better feedback for monitoring and control purposes.

Choosing the right materials is essential for durability and performance. Consider factors such as environmental conditions and load requirements when selecting materials for rails, carriages, and accessories.

Customizing ring track systems plays a vital role in enhancing precision and efficiency in various industries. By understanding the components, types, and applications of these systems, you can tailor them to meet your specific operational needs. Furthermore, investing in professional installation and maintenance ensures that your system will perform optimally over time. Embrace the potential of customizable ring track systems to unlock new levels of precision in your manufacturing processes.

Hot Tags:

Related News