Why Quality Driven Track Systems Are Crucial for Manufacturing Success

Jun 15,2025

Quality track systems are built to withstand the rigors of constant use. They are crafted from robust materials that resist wear and tear, ensuring a longer lifespan. This reliability translates to less frequent replacements and repairs, allowing manufacturers to maintain their production schedules without interruptions.

In manufacturing, precision is paramount. High-quality track systems enable equipment to operate with high accuracy, which is critical for tasks that require tight tolerances. This precision not only improves the quality of the final product but also enhances the efficiency of the production process.

Quality track systems contribute significantly to workplace safety. Well-designed and maintained tracks reduce the risk of accidents and equipment malfunctions. Compliance with safety standards is crucial in manufacturing, not just for legal reasons, but also for protecting employees and the company's reputation.

While the initial investment in quality track systems may be higher, the long-term savings are significant. Reduced downtime, lower maintenance costs, and increased productivity all contribute to a better return on investment.

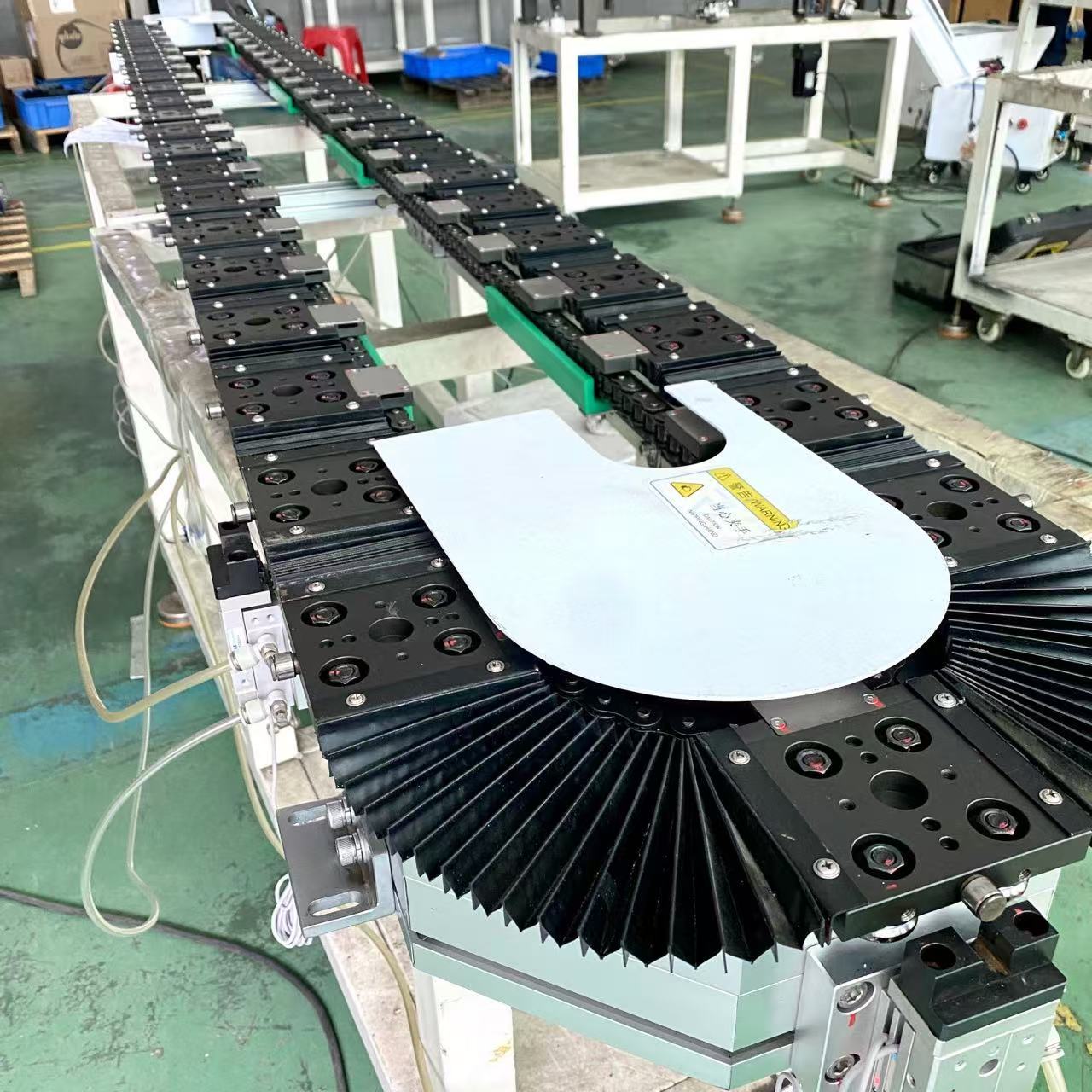

Rails form the backbone of any track system. They must be manufactured with precision and from materials that can endure the stresses of the manufacturing environment. Common materials include stainless steel and specialized alloys designed for maximum durability.

Bearings facilitate smooth movement along the rails. High-quality bearings reduce friction, which minimizes wear and helps maintain speed and precision in the manufacturing process.

The precision provided by high-quality track systems directly impacts the caliber of the products produced. Consistency in manufacturing processes leads to fewer defects and higher customer satisfaction.

Quality track systems are often designed with flexibility in mind, allowing manufacturers to adapt quickly to changing production demands. This adaptability is key in an ever-evolving market.

With robust materials and superior construction, quality track systems typically require less maintenance. This means less time and money spent on repairs, allowing resources to be allocated elsewhere.

An efficient track system helps streamline workflow by ensuring that materials and components move seamlessly throughout the production line. This reduces bottlenecks and enhances overall productivity.

When machinery operates smoothly due to quality track systems, it consumes less energy. This not only reduces operational costs but also promotes sustainability—a growing concern in manufacturing.

The rise of automation in manufacturing necessitates more advanced track systems. Automated guided vehicles (AGVs) and robotic systems require highly reliable and precise track systems for optimal functionality.

Integration of IoT (Internet of Things) technologies is becoming commonplace. Smart track systems equipped with sensors can provide real-time data on performance and maintenance needs.

With increasing emphasis on sustainability, manufacturers are seeking eco-friendly track systems that minimize environmental impact. Innovations in materials and design will play a crucial role in this trend.

As manufacturing processes become more specialized, the demand for customizable track systems is growing. Providers will need to offer solutions tailored to specific operational needs.

Quality-driven track systems are indispensable for manufacturing success. Their impact on operational efficiency, product quality, and overall profitability cannot be overlooked. By understanding the components that make up high-quality track systems, recognizing their advantages, and adhering to best maintenance practices, manufacturers can position themselves for long-term success in an increasingly competitive market.

Investing in quality track systems not only enhances productivity but also ensures a safer and more reliable manufacturing environment. As technology continues to evolve, staying ahead of trends in track systems will be essential for those seeking to thrive in the manufacturing industry.

Hot Tags:

Related News