How Precision Circular Conveyors Enhance Manufacturing Efficiency

Mar 31,2025

How Precision Circular Conveyors Enhance Manufacturing Efficiency

Table of Contents

1. Introduction to Precision Circular Conveyors

2. Understanding Circular Conveyors and Their Functionality

3. Key Benefits of Precision Circular Conveyors for Manufacturing Efficiency

4. Applications of Precision Circular Conveyors Across Various Industries

5. Design Features That Enhance Performanc

How Precision Circular Conveyors Enhance Manufacturing Efficiency

Table of Contents

- 1. Introduction to Precision Circular Conveyors

- 2. Understanding Circular Conveyors and Their Functionality

- 3. Key Benefits of Precision Circular Conveyors for Manufacturing Efficiency

- 4. Applications of Precision Circular Conveyors Across Various Industries

- 5. Design Features That Enhance Performance

- 6. Maintenance Best Practices for Optimal Performance

- 7. Future Trends in Circular Conveyor Technology

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Precision Circular Conveyors

In the fast-paced world of manufacturing, efficiency is paramount. Precision circular conveyors have emerged as a game-changing solution for businesses seeking to streamline their processes. These innovative systems not only improve material handling but also enhance the overall productivity of manufacturing operations. This article delves into the intricacies of precision circular conveyors, discussing their features, benefits, and applications across various industries.

2. Understanding Circular Conveyors and Their Functionality

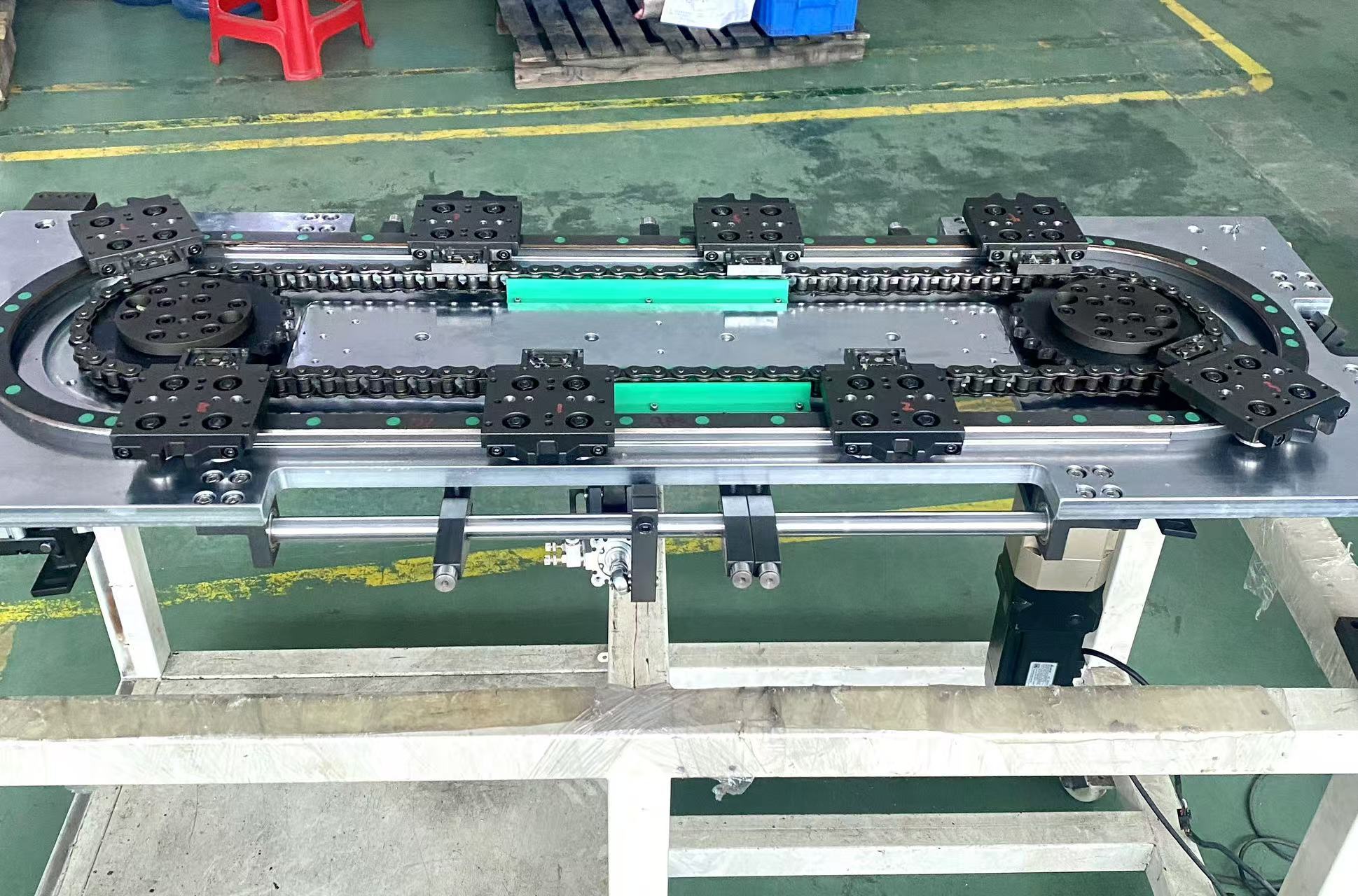

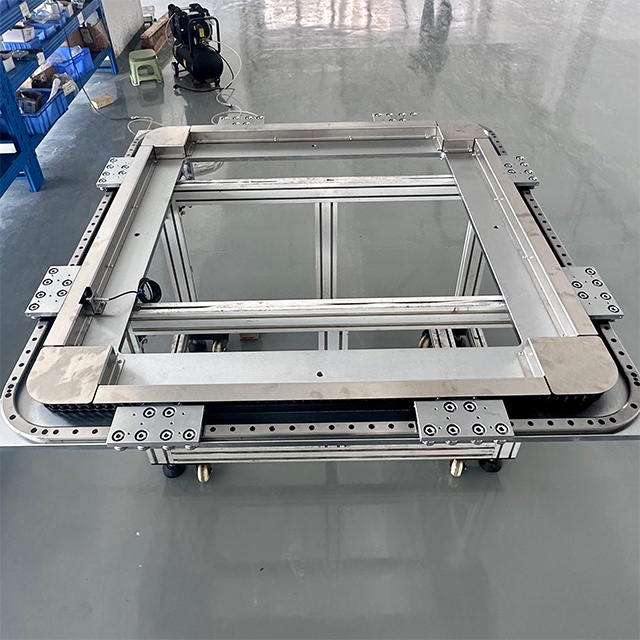

Circular conveyors are designed to transport materials efficiently in a continuous loop. Unlike traditional linear conveyors, these systems provide a seamless flow of goods, reducing downtime and optimizing workspace. Precision circular conveyors utilize advanced technology to ensure accurate positioning and reliable performance.

2.1 How Circular Conveyors Work

The operational mechanics of circular conveyors involve a series of rollers or belts arranged in a circular pathway. As materials enter the system, they are guided along the path, allowing for easy transport to various stages of manufacturing. The precision in their design allows for controlled movement, ensuring that items are delivered to the right place at the right time.

2.2 Types of Precision Circular Conveyors

There are several types of precision circular conveyors, including:

- **Rotating tables**, which are ideal for sorting and organizing products.

- **Indexing conveyors**, designed for tasks requiring precise positioning and timing.

- **Multi-tier conveyors**, suitable for maximizing vertical space in production environments.

Understanding these variations helps in selecting the right conveyor system for specific manufacturing needs.

3. Key Benefits of Precision Circular Conveyors for Manufacturing Efficiency

Precision circular conveyors offer numerous benefits that significantly enhance manufacturing efficiency:

3.1 Increased Production Speed

By facilitating a continuous flow of materials, circular conveyors reduce bottlenecks in the production line. Their ability to move goods swiftly from one station to another minimizes delays, leading to faster production cycles.

3.2 Space Optimization

Circular conveyors can be designed to fit compact spaces, allowing manufacturers to utilize their floor space more effectively. This optimized layout can lead to substantial savings on operational costs and improved workflow.

3.3 Enhanced Safety

With fewer moving parts exposed and a streamlined design, precision circular conveyors can contribute to a safer working environment. They reduce the risk of accidents associated with traditional conveyor systems, protecting both employees and products.

3.4 Improved Material Handling

These conveyors can handle various materials, from lightweight components to heavier items, making them versatile for multiple applications. This adaptability ensures that manufacturing processes remain efficient, regardless of the materials in use.

3.5 Reduced Labor Costs

By automating material transport, precision circular conveyors can decrease the need for manual handling, which in turn reduces labor costs. This allows companies to allocate human resources to more critical tasks that require skill and oversight.

4. Applications of Precision Circular Conveyors Across Various Industries

Precision circular conveyors are utilized in numerous sectors, showcasing their versatility and effectiveness.

4.1 Automotive Industry

In the automotive sector, these conveyors are essential for moving components through assembly lines, ensuring that parts are delivered efficiently for installation.

4.2 Food and Beverage Industry

In this industry, precision circular conveyors help in transporting packaged goods and raw materials, adhering to strict hygiene standards while maintaining speed and efficiency.

4.3 Pharmaceuticals

Pharmaceutical companies rely on these conveyors for the precise handling of delicate materials, ensuring that products are transported safely and securely through various production stages.

4.4 Electronics Manufacturing

In electronics manufacturing, precision circular conveyors facilitate the efficient transport of sensitive components, minimizing the risk of damage and ensuring timely delivery.

4.5 Packaging Industry

These conveyors play a crucial role in the packaging sector, streamlining the workflow by transporting products to packaging stations with precision and speed.

5. Design Features That Enhance Performance

The effectiveness of precision circular conveyors is rooted in their advanced design features:

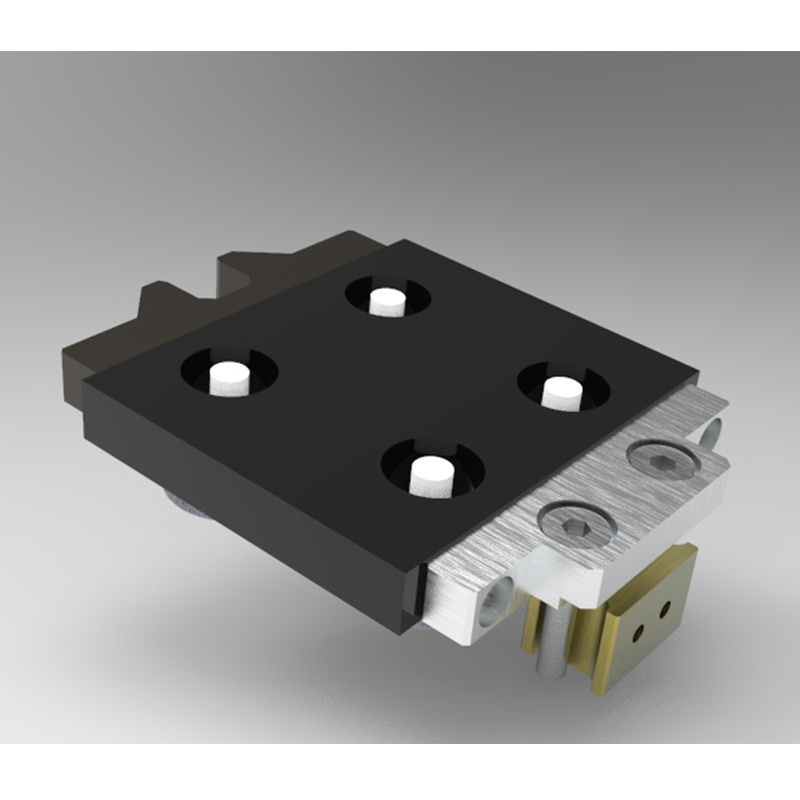

5.1 Modular Design

Many precision circular conveyors feature a modular design, allowing for easy customization and scalability. This flexibility enables manufacturers to adapt their systems as production demands change.

5.2 Advanced Control Systems

State-of-the-art control systems enhance the functionality of circular conveyors, providing real-time monitoring and automated adjustments to optimize performance.

5.3 Durable Materials

Constructed from high-quality materials, these conveyors are designed to withstand the rigors of manufacturing environments. Their durability ensures a longer lifespan and reduced maintenance costs.

5.4 Energy Efficiency

Many modern precision circular conveyors are designed with energy efficiency in mind, utilizing advanced motors and drive systems to reduce power consumption, which contributes to lower operational costs.

6. Maintenance Best Practices for Optimal Performance

Maintaining precision circular conveyors is crucial for ensuring they operate at peak efficiency. Here are some best practices:

6.1 Regular Inspections

Conducting regular inspections helps identify any potential issues before they escalate. Check for wear and tear, misalignment, and any signs of damage.

6.2 Lubrication and Cleaning

Keeping conveyor parts clean and well-lubricated prevents friction and ensures smooth operations. Establish a routine cleaning schedule to maintain hygiene, especially in food-related industries.

6.3 Timely Repairs

Addressing repairs promptly can prevent minor issues from becoming major setbacks. Keeping a stock of essential spare parts can minimize downtime when repairs are necessary.

6.4 Staff Training

Training staff on proper operational practices and maintenance procedures can greatly enhance the lifespan and performance of precision circular conveyors.

7. Future Trends in Circular Conveyor Technology

As technology continues to advance, several trends are emerging in the field of precision circular conveyors:

7.1 Automation and Smart Technology

The integration of AI and IoT technology is set to revolutionize how circular conveyors function, allowing for smarter operations and enhanced monitoring capabilities.

7.2 Sustainable Practices

With an increasing focus on sustainability, manufacturers are developing more eco-friendly conveyor systems that minimize environmental impact while maximizing efficiency.

7.3 Customization and Flexibility

Future conveyor systems are expected to offer even more customization options, allowing manufacturers to tailor solutions to their specific needs, enhancing productivity and efficiency.

8. Conclusion

Precision circular conveyors play a vital role in modern manufacturing, enhancing efficiency, safety, and productivity across various industries. By understanding their functionality, benefits, and applications, businesses can make informed decisions about integrating these systems into their operations. As technology advances, the potential for circular conveyors will only continue to grow, ensuring that they remain a key component in the future of manufacturing.

9. Frequently Asked Questions

9.1 What is a precision circular conveyor?

A precision circular conveyor is an advanced material handling system designed to transport goods in a continuous circular motion, optimizing efficiency and workflow in manufacturing processes.

9.2 How do precision circular conveyors improve manufacturing efficiency?

They enhance manufacturing efficiency by increasing production speed, optimizing space, improving material handling, enhancing safety, and reducing labor costs.

9.3 In which industries are precision circular conveyors commonly used?

Precision circular conveyors are utilized in various industries, including automotive, food and beverage, pharmaceuticals, electronics manufacturing, and packaging.

9.4 What maintenance is required for precision circular conveyors?

Regular inspections, lubrication, cleaning, timely repairs, and staff training are essential for maintaining optimal performance.

9.5 What are the future trends in circular conveyor technology?

Future trends include the integration of automation and smart technology, a focus on sustainable practices, and increased customization and flexibility in design.

Hot Tags:

Related News