Customization Options for Rectangle Circular Conveyors: Comprehensive Insights and Considerations

Apr 20,2025

Customization Options for Rectangle Circular Conveyors: Comprehensive Insights and Considerations

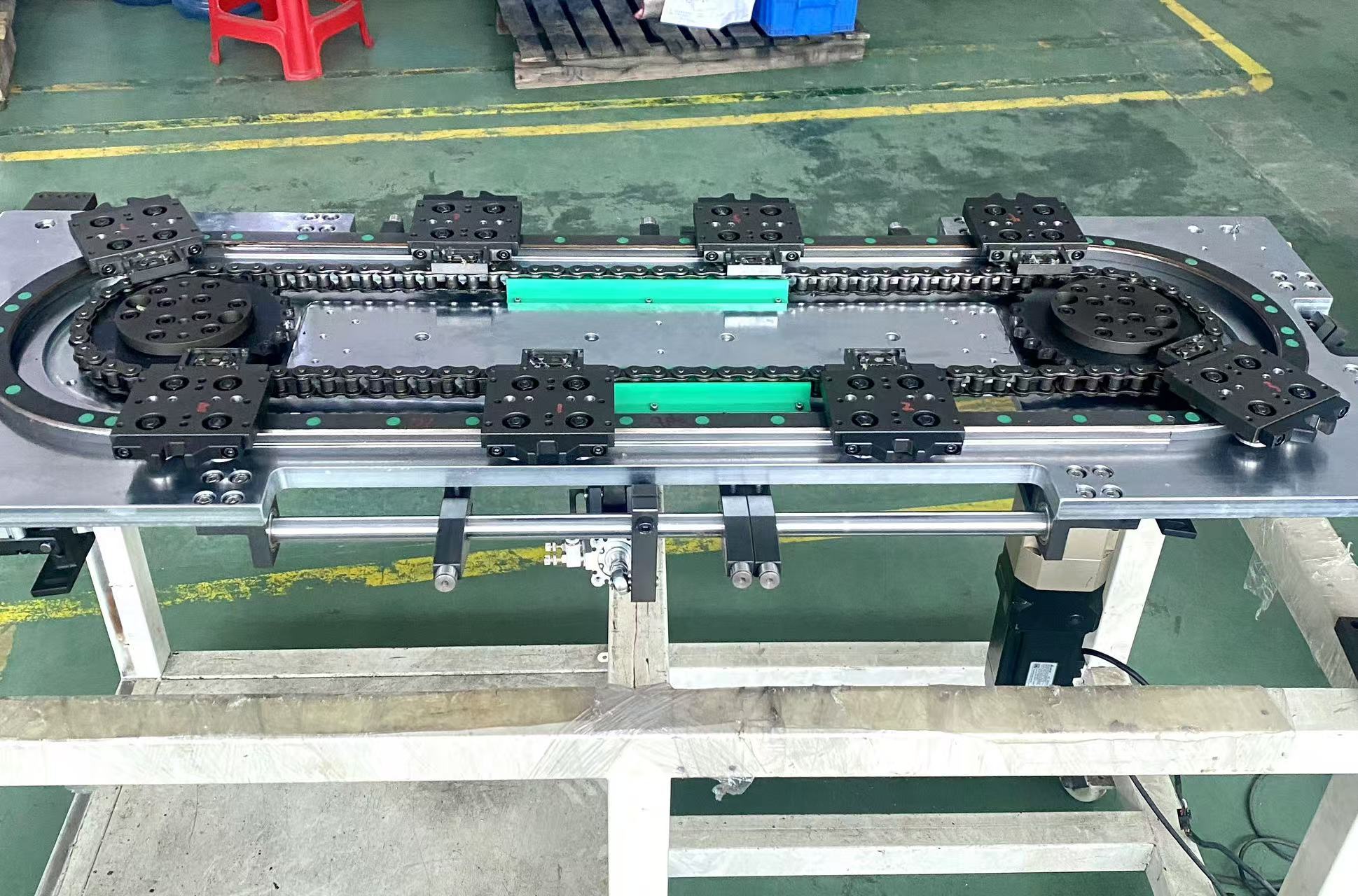

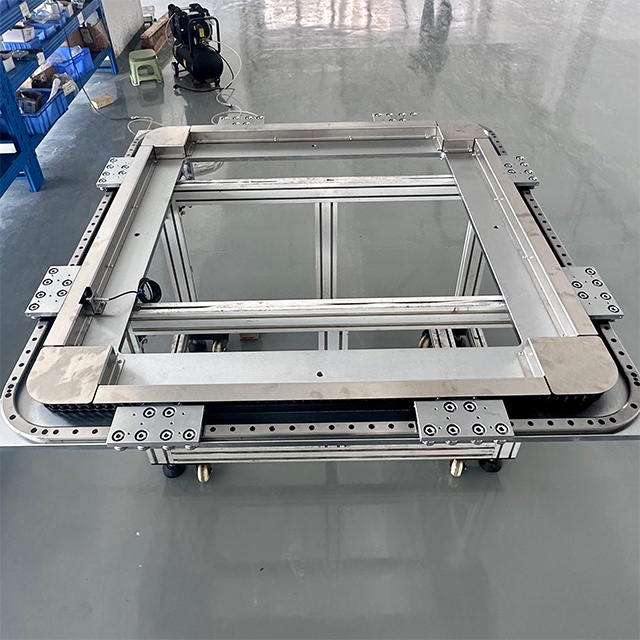

In the realm of industrial equipment, rectangle circular conveyors play a pivotal role in enhancing operational efficiency and streamlining processes. These conveyors are particularly valued for their ability to transport materials in a continuous loop, making them ideal for various applications in manufacturing and logistics. However, to maximize their effectiveness, it is essential to consider the customization options available. This article delves into the myriad customization choices for rectangle circular conveyors, offering detailed insights to help businesses make informed decisions.

Table of Contents

- 1. Introduction to Rectangle Circular Conveyors

- 2. Understanding Customization Options

- 3. Key Design Features to Customize

- 4. Enhancing Efficiency and Safety

- 5. Application-Specific Customizations

- 6. Future Trends in Conveyor Technology

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to Rectangle Circular Conveyors

Rectangle circular conveyors offer a unique solution for transporting materials within a defined space. Their design allows for continuous movement, making them suitable for tasks that require repetitive handling of items. Often utilized in assembly lines, packaging, and distribution centers, these conveyors can be tailored to fit a variety of operational requirements. Understanding the customization options available can greatly enhance their functionality and effectiveness in your specific application.

2. Understanding Customization Options

Customization options for rectangle circular conveyors are vast and can significantly impact operational efficiency. By tailoring these systems to meet specific needs, businesses can improve workflow and reduce downtime.

2.1 Types of Rectangle Circular Conveyors

There are several types of rectangle circular conveyors available, each designed for different applications:

- Powered Roller Conveyors: Ideal for moving heavy items, powered roller conveyors utilize motors to drive rollers.

- Belt Conveyors: These conveyors use a belt to transport materials and are suitable for a wide range of products.

- Chain Conveyors: Perfect for heavy-duty applications, chain conveyors provide robust support for large items.

2.2 Material Options for Conveyors

Choosing the right materials for the conveyor can greatly affect durability and maintenance. Common materials include:

- Steel: Known for its strength and resilience, steel is often used in heavy-duty applications.

- Aluminum: Lightweight and corrosion-resistant, aluminum is a great option for environments where weight is a concern.

- Plastic: Ideal for food processing, plastic conveyors are easy to clean and are resistant to chemicals.

3. Key Design Features to Customize

The design of rectangle circular conveyors can be customized in several ways to enhance performance and efficiency.

3.1 Belt Design and Specifications

The belt is one of the most critical components of any conveyor system. Customization options include:

- Belt Width and Thickness: Depending on the materials being transported, the width and thickness of the belt can be adjusted to accommodate varying weights and sizes.

- Belt Material: Options include rubber for flexibility and grip, or PVC for resistance to chemicals and oils.

- Belt Profile: Custom profiles can prevent slippage and allow for efficient material handling.

3.2 Drive Systems: Options and Benefits

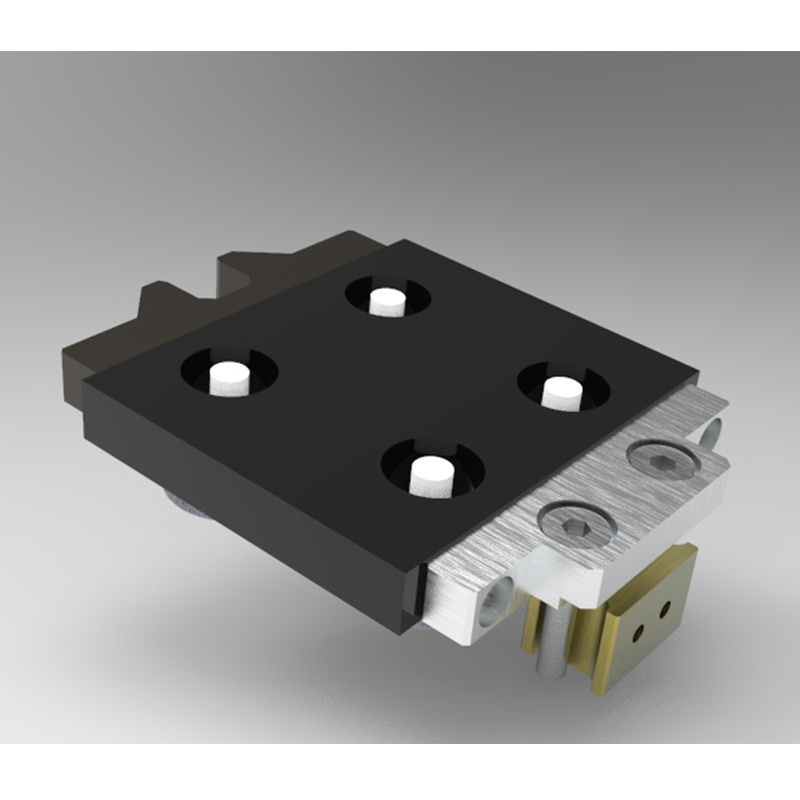

The drive system is integral to the operation of the conveyor. Customization can include:

- Motor Size: The size and power of the motor can be customized depending on the load capacity and speed requirements.

- Positioning of Drive Units: Whether to place the drive units at the ends or in the center can affect space and efficiency.

4. Enhancing Efficiency and Safety

Safety and efficiency are paramount in any industrial setting. The right customizations can help in achieving these goals.

4.1 Safety Features in Custom Conveyors

Incorporating safety features in the design of rectangle circular conveyors is essential. Considerations include:

- Guardrails: Help prevent items from falling off the conveyor.

- Emergency Stops: Allow for immediate halting of the conveyor in case of an emergency.

- Safety Sensors: Detect obstructions and automatically shut down the system to prevent accidents.

4.2 Energy Efficiency Considerations

In today's environmentally conscious climate, energy efficiency is a significant concern. Customization can lead to:

- Energy-Efficient Motors: These help reduce power consumption while maintaining operational performance.

- Variable Speed Drives: Allow for adjustments in speed based on workload, further enhancing energy savings.

5. Application-Specific Customizations

Different industries have unique requirements. Customization should reflect these specific needs.

5.1 Custom Conveyors in the Food Industry

In the food industry, hygiene and compliance with regulations are critical. Customizations may include:

- Food-Grade Materials: Ensure that all materials are safe for food handling.

- Easy-Clean Designs: Incorporate features that allow for efficient cleaning and maintenance.

5.2 Manufacturing Applications

In manufacturing, customization can lead to improved productivity. Considerations include:

- Integration with Other Systems: Custom conveyors can be designed to integrate seamlessly with existing manufacturing systems.

- Modular Configurations: Allow for flexibility and adaptability as production needs change.

6. Future Trends in Conveyor Technology

The conveyor industry is continually evolving. Future trends may include:

- Automation and Smart Technology: Implementing sensors and AI to improve efficiency and monitoring.

- Sustainable Practices: Using eco-friendly materials and energy sources in conveyor design and operation.

7. Frequently Asked Questions

What are the key benefits of customizing a rectangle circular conveyor?

Customizing a rectangle circular conveyor allows businesses to enhance efficiency, ensure safety, and meet specific operational needs.

How can I choose the right materials for my conveyor system?

Consider the type of materials being transported, environmental conditions, and compliance requirements to select the appropriate materials.

Are there any safety standards I should follow for conveyor systems?

Yes, compliance with safety standards such as OSHA and ANSI is crucial to ensure the safe operation of conveyor systems.

Can I integrate a custom conveyor with existing machinery?

Yes, many custom conveyors are designed to integrate seamlessly with existing production and logistics systems.

What trends should I be aware of in conveyor technology?

Keep an eye on automation, smart technology, and sustainable practices as key trends in the conveyor industry.

8. Conclusion

In conclusion, understanding the customization options for rectangle circular conveyors is vital for optimizing their performance in various industrial settings. By carefully selecting the right materials, designs, and safety features, businesses can tailor conveyor systems to meet their unique operational needs. With advancements in technology and growing trends towards automation and sustainability, the future of conveyor systems promises even greater efficiency and innovation. Investing in customized solutions today can pave the way for improved productivity and a competitive edge in the marketplace.

Hot Tags:

Related News