Enhancing Efficiency with Oval Circular Conveyors: A Comprehensive Guide

Apr 15,2025

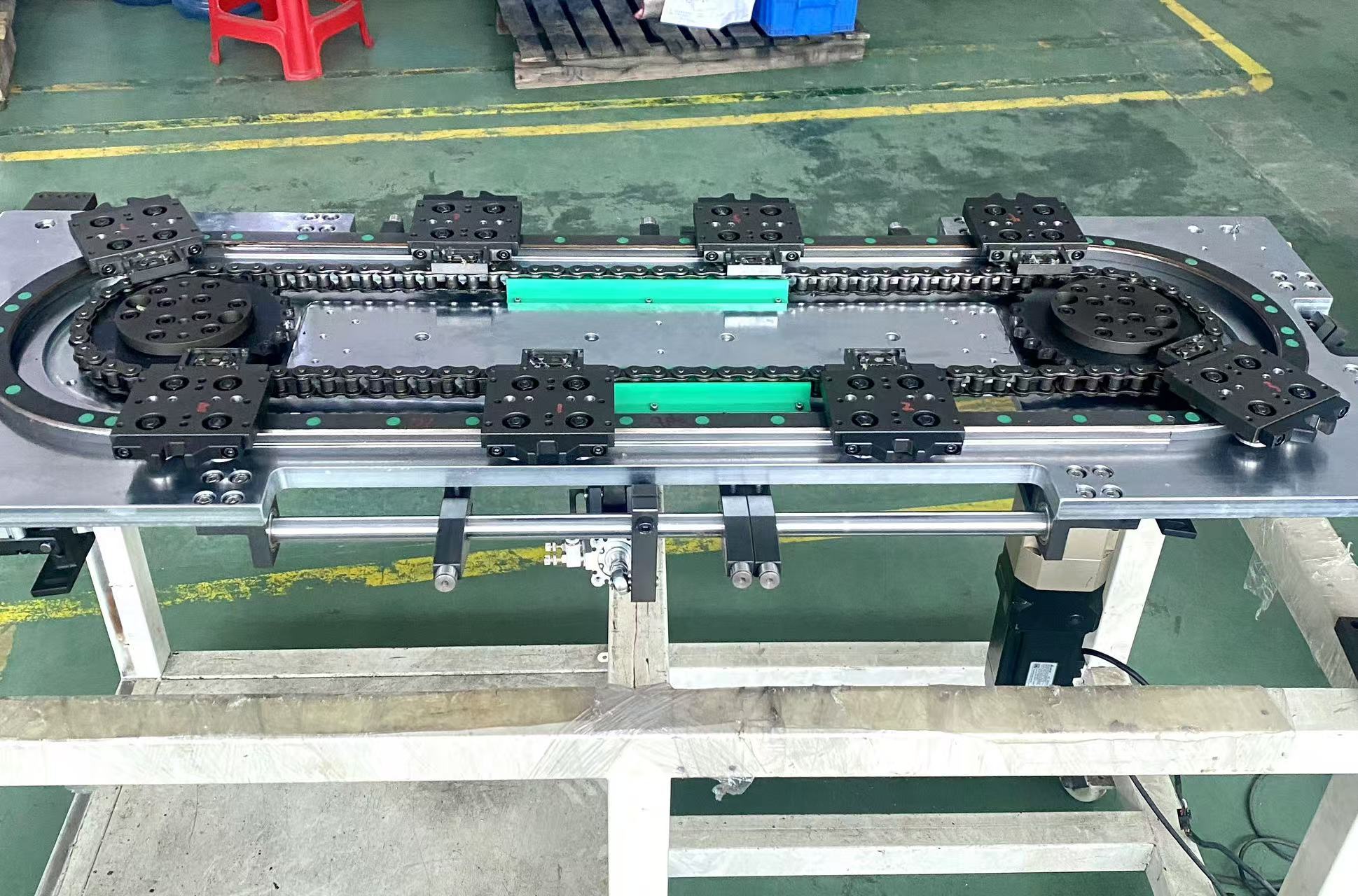

In the realm of industrial equipment and components, oval circular conveyors have become a significant asset for businesses looking to enhance their production efficiency. These unique conveyor systems are designed to facilitate the seamless movement of materials in a continuous loop, making them ideal for various applications across industries.

One of the primary advantages of oval circular conve

In the realm of industrial equipment and components, oval circular conveyors have become a significant asset for businesses looking to enhance their production efficiency. These unique conveyor systems are designed to facilitate the seamless movement of materials in a continuous loop, making them ideal for various applications across industries.

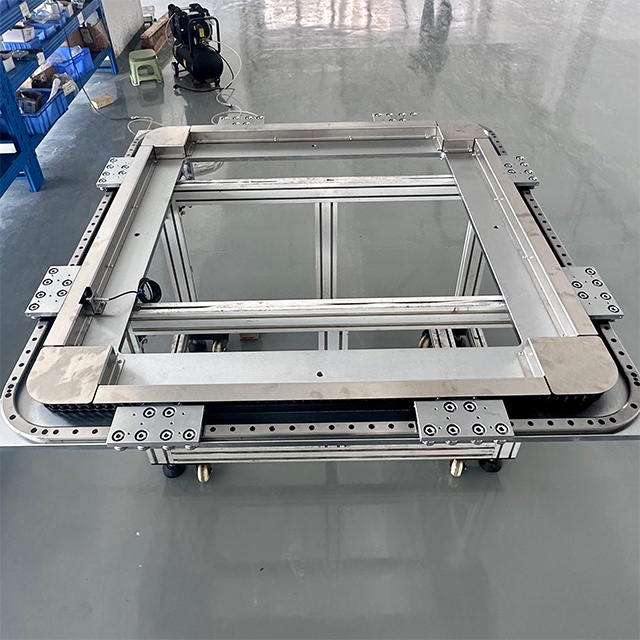

One of the primary advantages of oval circular conveyors is their space-saving design. Unlike traditional linear conveyors that require straight paths and ample floor space, oval circular conveyors can fit into compact areas. This characteristic allows manufacturers to optimize their layout while maintaining efficient material flow. Their rounded design enables products to be carried smoothly, reducing the risk of damage and enhancing the overall handling process.

Another key benefit of oval circular conveyors is their ability to handle a wide range of products. Whether dealing with lightweight materials or heavier loads, these conveyors can be customized to meet specific operational needs. The versatility offered by oval circular conveyors makes them suitable for various industries, including food and beverage, packaging, and manufacturing. They can transport goods through different stages of production, from assembly to packaging, ensuring a streamlined workflow.

Moreover, oval circular conveyors often incorporate advanced technology that enhances their functionality. Features such as adjustable speed controls and automated tracking systems allow for real-time monitoring and adjustments, providing greater control over the entire conveyor process. This technological integration not only improves efficiency but also reduces the likelihood of human error, which can lead to costly mistakes in production.

Maintenance is another crucial aspect of conveyor systems. Oval circular conveyors are generally easier to maintain than their traditional counterparts due to their simplified design and fewer moving parts. Regular maintenance routines can be established to ensure that these systems operate at peak performance, minimizing downtime and maximizing productivity.

When considering the implementation of an oval circular conveyor system, it's essential to assess the specific requirements of your operation. Factors such as the type of products being transported, the desired speed, and the layout of your facility will influence the design and setup of the conveyor system. Collaborating with experts in conveyor technology can provide valuable insights and help tailor a solution that fits your unique needs.

In summary, oval circular conveyors represent a forward-thinking solution in the industrial equipment sector. Their efficient design, adaptability, and reduced maintenance requirements make them a valuable addition to any production line. By investing in an oval circular conveyor system, businesses can enhance their operational efficiency, reduce costs, and ultimately improve their bottom line.

One of the primary advantages of oval circular conveyors is their space-saving design. Unlike traditional linear conveyors that require straight paths and ample floor space, oval circular conveyors can fit into compact areas. This characteristic allows manufacturers to optimize their layout while maintaining efficient material flow. Their rounded design enables products to be carried smoothly, reducing the risk of damage and enhancing the overall handling process.

Another key benefit of oval circular conveyors is their ability to handle a wide range of products. Whether dealing with lightweight materials or heavier loads, these conveyors can be customized to meet specific operational needs. The versatility offered by oval circular conveyors makes them suitable for various industries, including food and beverage, packaging, and manufacturing. They can transport goods through different stages of production, from assembly to packaging, ensuring a streamlined workflow.

Moreover, oval circular conveyors often incorporate advanced technology that enhances their functionality. Features such as adjustable speed controls and automated tracking systems allow for real-time monitoring and adjustments, providing greater control over the entire conveyor process. This technological integration not only improves efficiency but also reduces the likelihood of human error, which can lead to costly mistakes in production.

Maintenance is another crucial aspect of conveyor systems. Oval circular conveyors are generally easier to maintain than their traditional counterparts due to their simplified design and fewer moving parts. Regular maintenance routines can be established to ensure that these systems operate at peak performance, minimizing downtime and maximizing productivity.

When considering the implementation of an oval circular conveyor system, it's essential to assess the specific requirements of your operation. Factors such as the type of products being transported, the desired speed, and the layout of your facility will influence the design and setup of the conveyor system. Collaborating with experts in conveyor technology can provide valuable insights and help tailor a solution that fits your unique needs.

In summary, oval circular conveyors represent a forward-thinking solution in the industrial equipment sector. Their efficient design, adaptability, and reduced maintenance requirements make them a valuable addition to any production line. By investing in an oval circular conveyor system, businesses can enhance their operational efficiency, reduce costs, and ultimately improve their bottom line.

Hot Tags:

Related News