Revolutionizing Production: The Benefits of Precision Circular Conveyors

Mar 21,2025

Revolutionizing Production: The Benefits of Precision Circular Conveyors

Table of Contents

- 1. Introduction to Precision Circular Conveyors

- 2. Understanding Circular Conveyors in Industrial Applications

- 3. Advantages of Using Precision Circular Conveyors

- 4. Precision Engineering in Circular Conveyors

- 5. Applications of Precision Circular Conveyors Across Industries

- 6. Choosing the Right Precision Circular Conveyor System

- 7. The Future of Conveying Technology

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Precision Circular Conveyors

In today's fast-paced industrial environment, efficiency and precision are paramount. **Precision circular conveyors** have emerged as vital components in enhancing production lines, offering a seamless method to transport materials and products. These systems are engineered to deliver superior performance, improving productivity and minimizing downtime. This article explores the numerous benefits these conveyors bring to manufacturing processes, laying the groundwork for a deeper understanding of their role in modern industry.

2. Understanding Circular Conveyors in Industrial Applications

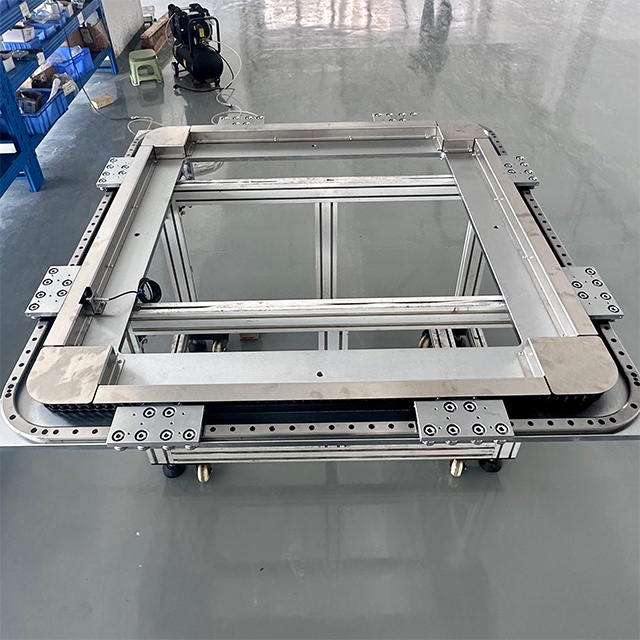

Precision circular conveyors are designed to facilitate the movement of goods in a continuous loop, allowing for effective handling of various materials. Unlike traditional linear conveyors, circular systems enable complex routing and sophisticated automation, which are crucial for modern production lines. Their design often includes advanced features such as programmable controls and sensors, providing a high level of flexibility and adaptability to various operational needs.

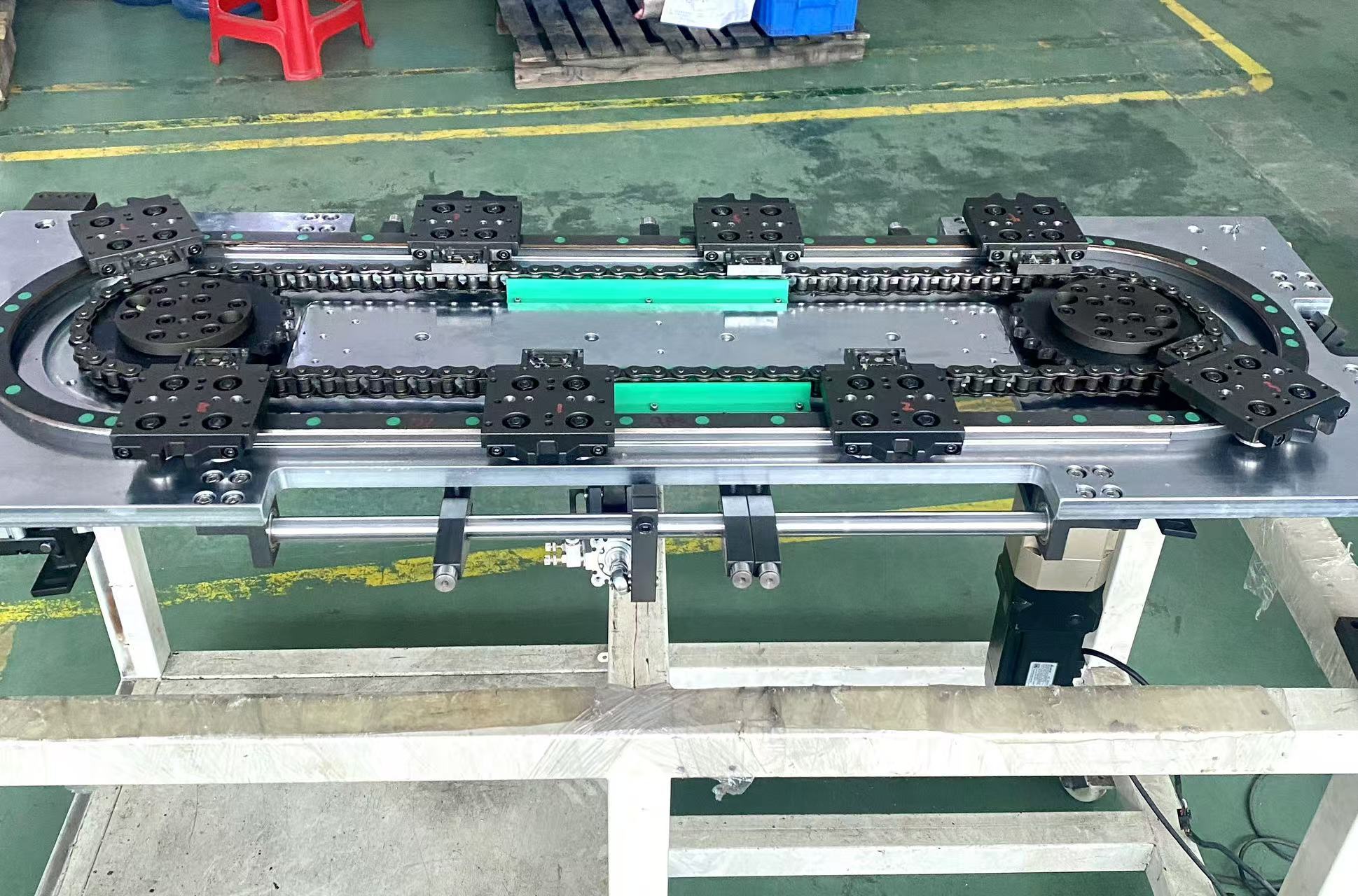

2.1 The Mechanics Behind Circular Conveyors

Circular conveyors operate on a simple yet effective principle. Materials are placed on a moving platform that rotates around a central axis, ensuring a smooth and consistent flow. This design minimizes the risk of jams and bottlenecks, which are common challenges in linear systems. With proper engineering, precision circular conveyors can handle a variety of shapes and sizes, making them versatile for multiple applications.

3. Advantages of Using Precision Circular Conveyors

Precision circular conveyors offer a multitude of benefits that can significantly impact productivity and operational efficiency. Understanding these advantages is essential for businesses looking to optimize their manufacturing processes.

3.1 Enhanced Operational Efficiency

One of the primary benefits of precision circular conveyors is their ability to enhance operational efficiency. By allowing for continuous material flow, these systems reduce the time spent on manual handling processes. Additionally, their design minimizes **product damage** and improves handling speed, ensuring that production targets are met without compromising quality.

3.2 Cost-Effectiveness

Investing in precision circular conveyors can lead to substantial cost savings over time. These systems require less maintenance than traditional conveyors, reducing operational costs. Furthermore, their ability to streamline production processes means that businesses can allocate resources more effectively, ultimately leading to increased profitability.

3.3 Space-Saving Design

In many industrial settings, space is at a premium. Precision circular conveyors are designed to occupy less floor space compared to traditional systems. Their compact design allows for efficient use of available resources, enabling manufacturers to maximize their production capabilities without the need for extensive facility alterations.

4. Precision Engineering in Circular Conveyors

The effectiveness of precision circular conveyors lies in their engineering. These conveyors are often constructed using high-quality materials and cutting-edge technology to ensure durability and reliability. **Precision engineering** plays a critical role in the design and functionality of these systems, allowing for accurate control of speed, position, and load handling.

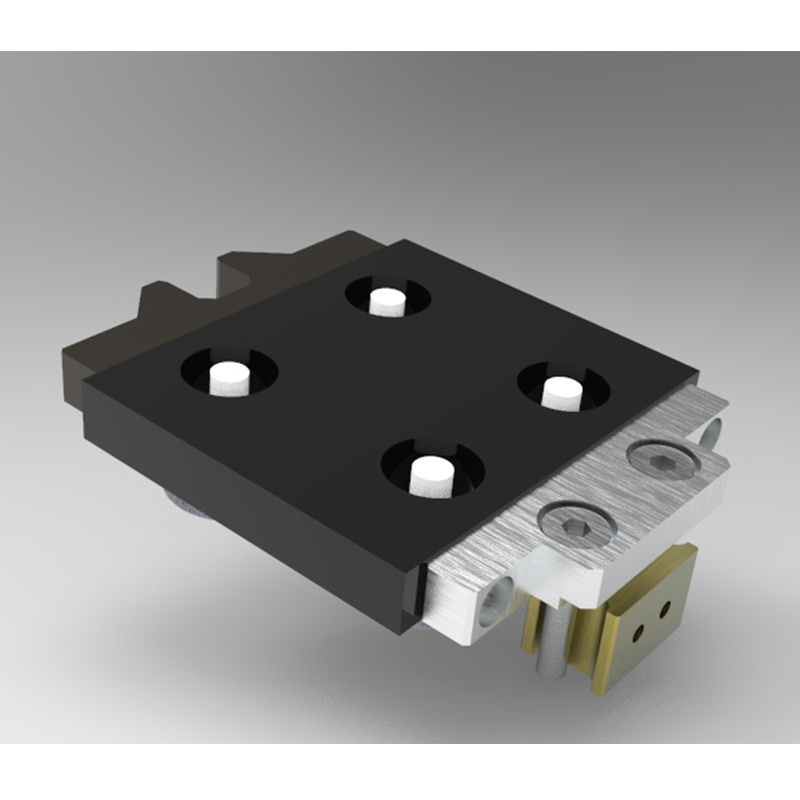

4.1 Key Components of Precision Circular Conveyors

The main components of precision circular conveyors include:

- **Drive Motors:** These provide the necessary power to move the conveyor.

- **Controllers:** Programmable logic controllers (PLCs) manage the speed and direction of the conveyor.

- **Sensors:** These detect the position and speed of materials, ensuring smooth operation.

- **Belts and Rollers:** Designed for optimal material handling, these components provide the necessary surface for product transport.

5. Applications of Precision Circular Conveyors Across Industries

Precision circular conveyors find applications across various sectors, showcasing their versatility and effectiveness in different operational environments.

5.1 Manufacturing

In the manufacturing sector, circular conveyors are utilized to transport components through different stages of production. Their ability to integrate with automated systems ensures a seamless workflow, reducing the need for manual intervention.

5.2 Food Processing

The food processing industry benefits significantly from precision circular conveyors due to their hygienic design and ability to handle delicate products without compromising quality. These systems are essential for efficiently transporting raw materials, ingredients, and finished products within processing plants.

5.3 Pharmaceutical

In pharmaceutical manufacturing, precision and cleanliness are non-negotiable. Circular conveyors can be designed to meet stringent regulatory requirements, ensuring that products are transported safely and efficiently throughout the production process.

6. Choosing the Right Precision Circular Conveyor System

Selecting the appropriate circular conveyor system requires careful consideration of several factors, including:

- **Load Capacity:** Assess the weight and volume of materials that need to be transported to choose a conveyor that can handle the demands.

- **Speed Requirements:** Determine the required speed for your operational processes, ensuring the conveyor can meet these needs.

- **Customization Needs:** Evaluate whether your processes require a conveyor system with specific features or configurations.

Engaging with a reliable manufacturer can provide insights into the best options tailored to your specific operational needs.

7. The Future of Conveying Technology

As technology continues to advance, the future of precision circular conveyors looks promising. Innovations in automation, artificial intelligence, and machine learning are expected to enhance the functionality of these systems. **Smart conveyors** equipped with data analytics capabilities will allow for real-time monitoring and adjustments, further improving efficiency and productivity.

8. Conclusion

Precision circular conveyors represent a groundbreaking advancement in industrial transport systems. Their ability to enhance efficiency, reduce costs, and save space makes them a valuable asset in various sectors. As industries continue to evolve, investing in state-of-the-art conveyor systems will be essential for businesses aiming to maintain a competitive edge. By embracing these innovations, companies can revolutionize their production processes and achieve unprecedented levels of productivity.

9. Frequently Asked Questions

What are precision circular conveyors used for?

Precision circular conveyors are primarily used to transport materials and products efficiently through manufacturing, food processing, and pharmaceutical production lines.

How do precision circular conveyors improve efficiency?

They enhance efficiency by enabling continuous material flow, reducing manual handling, and minimizing product damage, thereby speeding up production processes.

Are precision circular conveyors cost-effective?

Yes, they can lead to significant cost savings due to lower maintenance needs and improved operational efficiency, allowing for better resource allocation.

Can precision circular conveyors handle different types of materials?

Absolutely. Their design is versatile, allowing them to manage various shapes, sizes, and weights of materials depending on the specific application.

What factors should be considered when selecting a circular conveyor system?

Key factors include load capacity, speed requirements, space constraints, and any necessary customization features for specific operational needs.

Hot Tags:

Related News